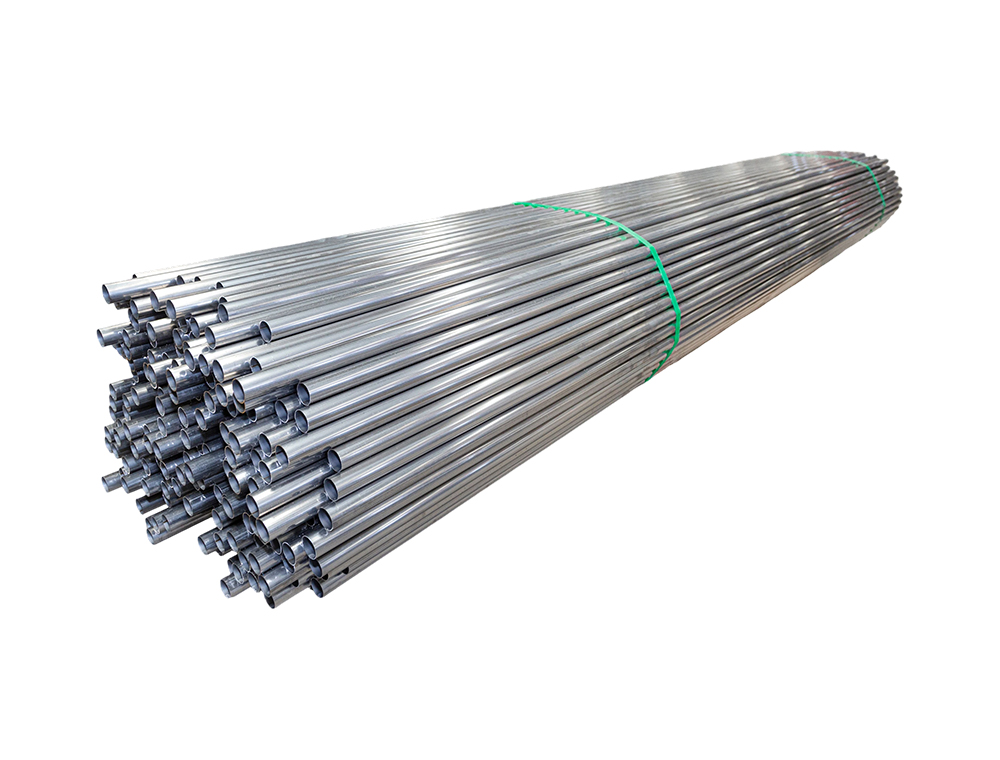

Stainless steel tube row are constructed from multiple stainless steel tubes arranged in a specific pattern, typically welded or mechanically assembled to form a single unit.

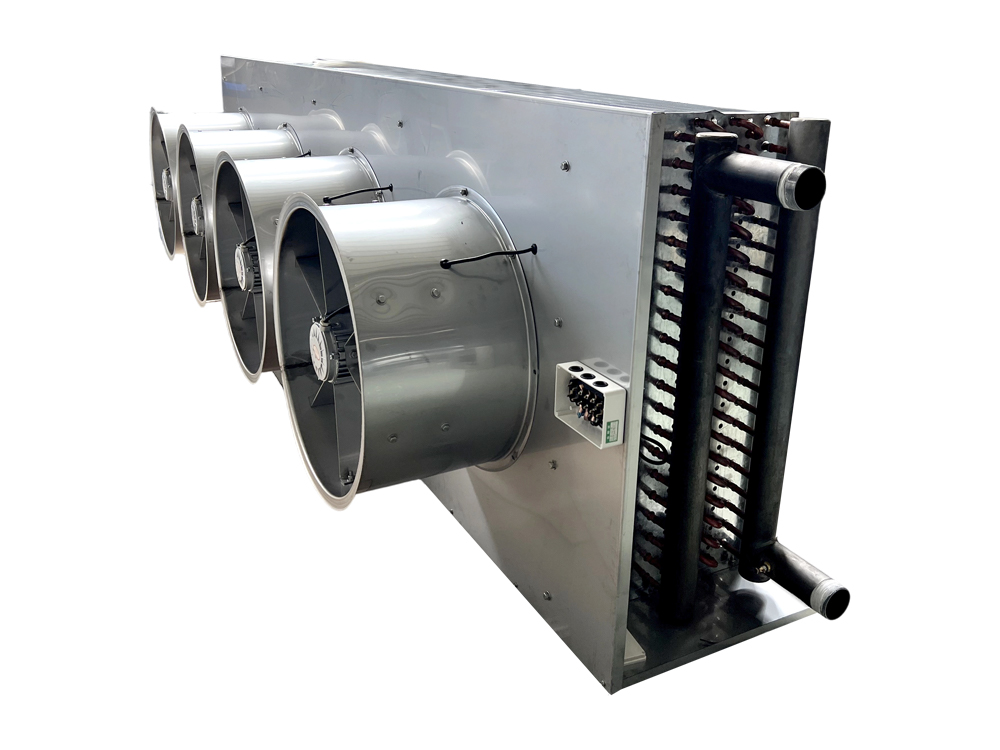

The manufacturing process includes precision forming, weld seam treatment, and surface treatment. The tube bank can be designed as a parallel, serpentine, or customized layout, with precise tube spacing and diameter configurations. These tube banks offer customizable flow characteristics, and their structural strength is directly related to the mechanical properties of the material.

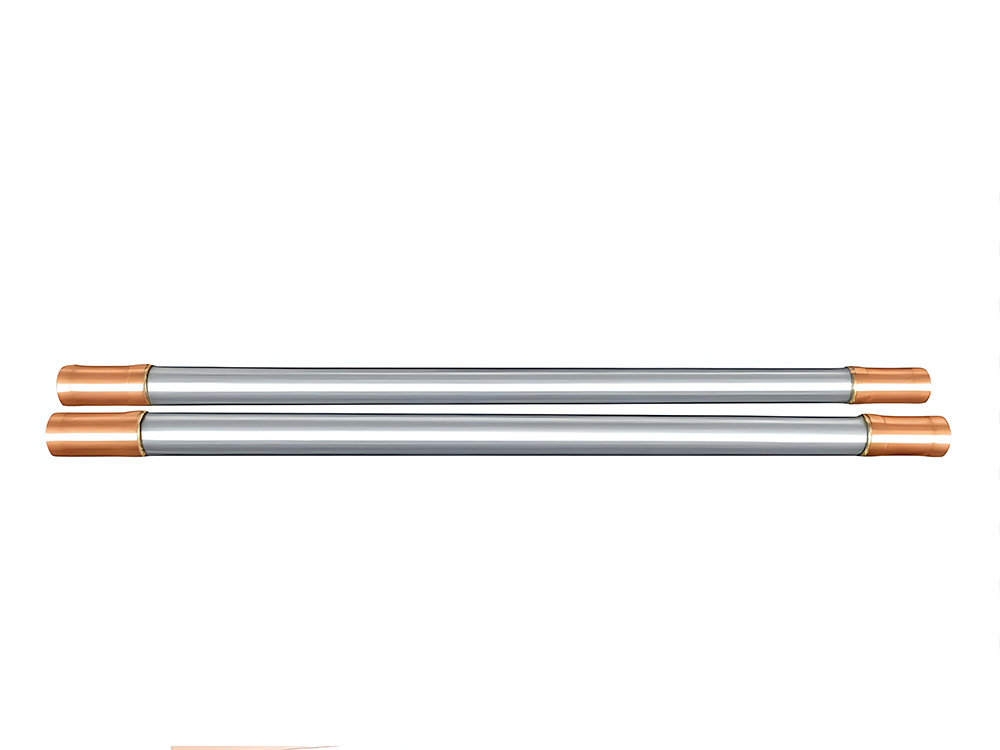

Surface treatments include polishing, sandblasting, and passivation, each resulting in a different surface finish. Stainless steel tube bank connection interfaces can be standardized or customized based on system requirements.

This product is widely used in industrial applications such as fluid transport and heat exchange, with an operating temperature range tailored to the physical properties of the selected stainless steel grade. Product specifications allow for customized design based on specific usage conditions.

English

English русский

русский Español

Español