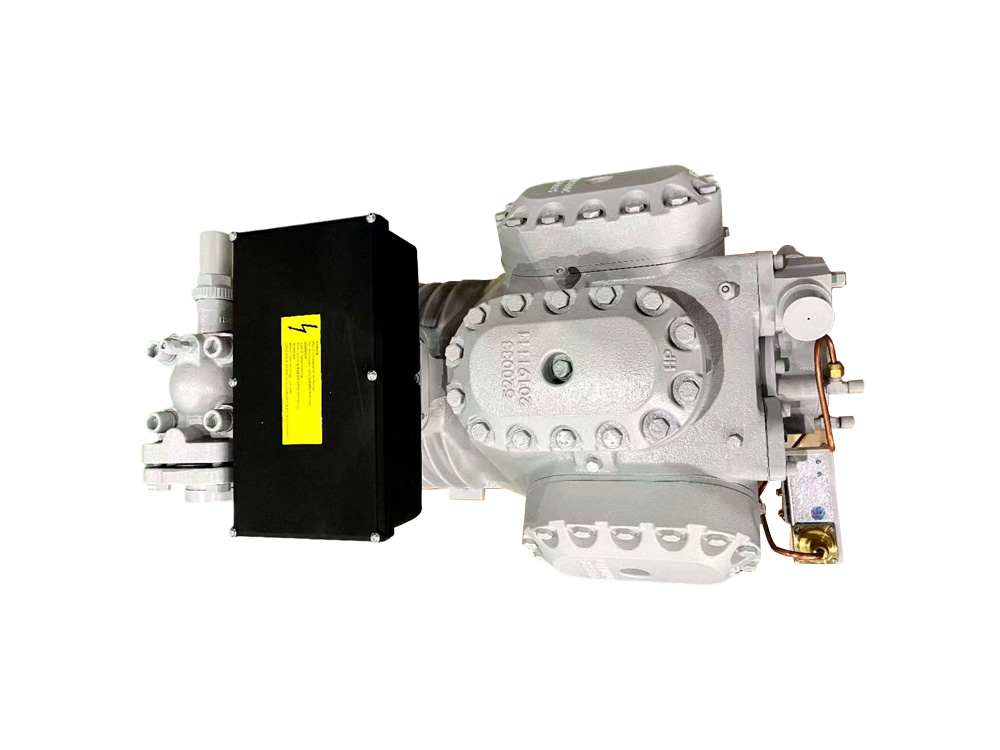

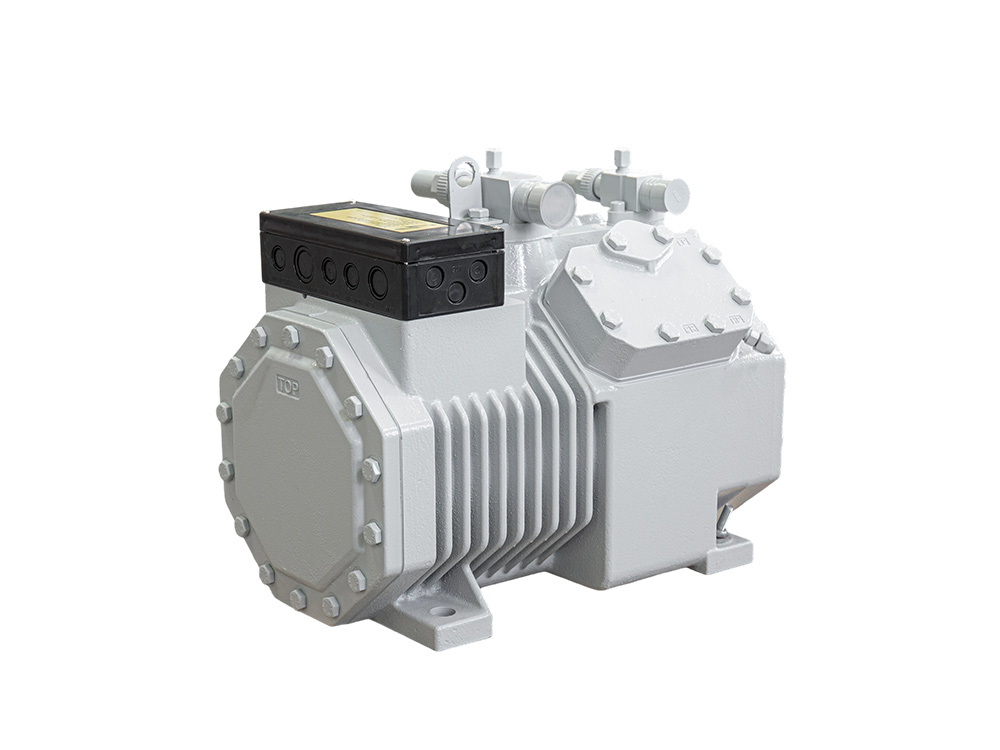

Semi-Hermetic Piston Compressors: The Industrial Refrigeration Workhorse

In the world of industrial and commercial refrigeration, the semi-hermetic piston compressor stands as a testament to durability, serviceability, and proven performance. Striking a perfect balance between sealed units and open-drive systems, these compressors power everything from cold storage warehouses to food processing plants globally. This guide delves into the critical knowledge surrounding this essential technology, incorporating the engineering expertise of Zhejiang Diya Refrigeration Equipment Co., Ltd., a manufacturer with over four decades of industry presence.

1. The Industrial Core: Selecting the Right Semi-Hermetic Piston Compressor

Choosing the correct semi-hermetic piston compressor is the cornerstone of an efficient and reliable refrigeration system. It requires a precise technical match, not just a horsepower estimate. Based on Zhejiang Diya's extensive manufacturing experience, focusing on these core parameters ensures an optimal selection:

- Refrigeration Capacity & Motor Power (HP/kW): Precisely calculated based on evaporating and condensing temperatures to prevent underperformance or energy waste.

- Operating Conditions (Evap/Condensing Temp): Defining the compressor's operational envelope (e.g., -35°C for freezing vs. +5°C for cooling) is critical as it dictates internal design differences.

- Refrigerant Type: Compatibility with R404A, R507A, or R22 affects material selection and performance curves.

- Design Working Pressure (Suction/Discharge): Ensures the compressor's structural integrity can handle the system's maximum pressure for safe operation.

Leveraging its integrated services from R&D to after-sales, Zhejiang Diya provides precise selection calculations and product matching for global clients, from the humid heat of Southeast Asia to the extreme ambient temperatures of the Middle East.

2. The Secret to Longevity: Three Pillars of Reliability in Design

The reputation of the semi-hermetic piston compressor as an "evergreen" in industrial refrigeration is built upon foundational reliability engineering. The products from Zhejiang Diya, exported to demanding markets like Europe and America, excel due to three key design philosophies:

- High-Strength Cast Iron Crankcase and Crankshaft: Provides a rigid foundation to withstand significant alternating stress, enabling a design life exceeding 100,000 operating hours.

- Forced Pressure Lubrication System: An integral mechanical oil pump ensures immediate lubrication to all bearings and friction points, even during start-up at evaporation temperatures as low as -40°C.

- Efficient and Wear-Resistant Valve Assemblies: Utilizes precision-ground valve plates and high-strength alloy valve strips to maintain a perfect seal under high-frequency operation, ensuring high volumetric efficiency.

Since its establishment in 1983, Zhejiang Diya has prioritized durability as a core design principle. Its ISO9001-certified quality management system ensures every step, from raw material to finished product, adheres to these high-reliability standards.

3. The Efficiency Evolution: Modern Energy-Saving Technologies

With rising global energy costs, the efficiency of a semi-hermetic piston compressor is paramount. Modern innovations have significantly boosted its Coefficient of Performance (COP). Zhejiang Diya focuses its energy-saving innovations on several key areas:

- Motor Optimization: Employing high-efficiency (IE3/IE4 class) motors to reduce electromagnetic and copper losses, directly lowering input power (kW).

- Cylinder Unloading Technology: Through capacity modulation (e.g., 0%, 50%, 100%), the compressor's output dynamically matches the actual cooling load, avoiding energy waste during part-load conditions.

- Enhanced Cooling Passage Design: Improved cooling airflow for the motor and cylinder head maintains lower operating temperatures, reducing discharge superheat and increasing real-world cooling efficiency.

As an R&D-focused modern enterprise, Zhejiang Diya's compressors integrate these technologies to help clients in regions with high electricity costs, such as Africa and the Americas, achieve substantial operational savings.

4. A Guide to Longevity: Full Lifecycle Maintenance from Installation to Overhaul

The extended service life of a quality semi-hermetic piston compressor relies equally on manufacturing excellence and proper maintenance. Drawing from vast engineering installation and after-sales experience, Zhejiang Diya outlines essential lifecycle maintenance practices:

Installation Phase

- Foundation Vibration Isolation: Use specialized vibration dampers to control vibration amplitude below 25μm.

- Piping Brazing and Cleanliness: Ensure the system is free of contaminants and copper oxide to prevent ingress into the cylinders.

Operational Maintenance

- Oil Monitoring: Regularly check oil level, color, and acidity. Change lubricant and oil filters as scheduled.

- Electrical Inspection: Monitor running current (A) and motor winding insulation resistance (should be >1MΩ).

Planned Major Overhaul

- A preventive overhaul is recommended after 8,000-16,000 operating hours, inspecting piston ring clearance, main and connecting rod bearing clearance, and valve seal integrity.

Zhejiang Diya's global service network ensures that professional maintenance guidance and genuine spare parts are accessible wherever the equipment is located, embodying the value of its one-stop service model.

5. Built for Challenge: Adaptive Designs for Harsh Environments

Semi-hermetic piston compressors must endure diverse and extreme environmental challenges worldwide. Zhejiang Diya's products are engineered for such demanding applications through targeted adaptive designs:

- For High-Temperature Environments (e.g., Middle East): Enhanced motor cooling and the use of high-temperature resistant insulation materials (Class F/H) ensure stable operation in machine rooms with ambient temperatures up to 52°C.

- For High-Humidity and Corrosive Environments (e.g., Coastal, Southeast Asia): Application of special anti-corrosion coatings on the housing and the use of more corrosion-resistant valve materials internally.

- For High-Load Continuous Operation (e.g., Chemical Plants, Large Cold Storage): Utilization of large, heavy-duty bearings and high-strength connecting rods to guarantee continuous operation under maximum design discharge pressures of 25 Bar.

Backed by the flexibility of its in-house manufacturing and the high standards mandated by CE certification, Zhejiang Diya provides customized compressor solutions tailored to the specific needs of different regions, ensuring reliable performance across the globe.

English

English русский

русский Español

Español