What are the key differences between 304/316L stainless steel pipe and stainless steel cylinder tube for industrial use?

In industrial applications, 304/316L stainless steel pipe and stainless steel cylinder tube are widely used due to their excellent corrosion resistance, mechanical strength, and adaptability to various operational conditions.

Material Composition and Mechanical Properties

304 vs 316L Stainless Steel

The primary difference between 304 and 316L stainless steel lies in their chemical composition. 304 stainless steel typically contains 18% chromium and 8% nickel, offering good corrosion resistance in general industrial environments. In contrast, 316L stainless steel incorporates molybdenum, which enhances resistance to pitting and crevice corrosion, particularly in chloride-rich environments such as marine or chemical applications.

Both 304/316L stainless steel pipe and stainless steel cylinder tube maintain high tensile strength, durability, and thermal stability, but their selection often depends on the specific industrial conditions, including exposure to chemicals, moisture, and temperature fluctuations.

Mechanical Strength and Structural Integrity

In terms of mechanical performance, stainless steel cylinder tube is generally preferred in high-pressure applications due to its seamless construction and uniform wall thickness. Conversely, welded 304/316L stainless steel pipe may offer cost advantages while maintaining acceptable strength for lower-pressure applications. Choosing the appropriate material ensures long-term operational stability and reduces the likelihood of maintenance issues or system failure.

Design and Structural Differences

Shape and Manufacturing Process

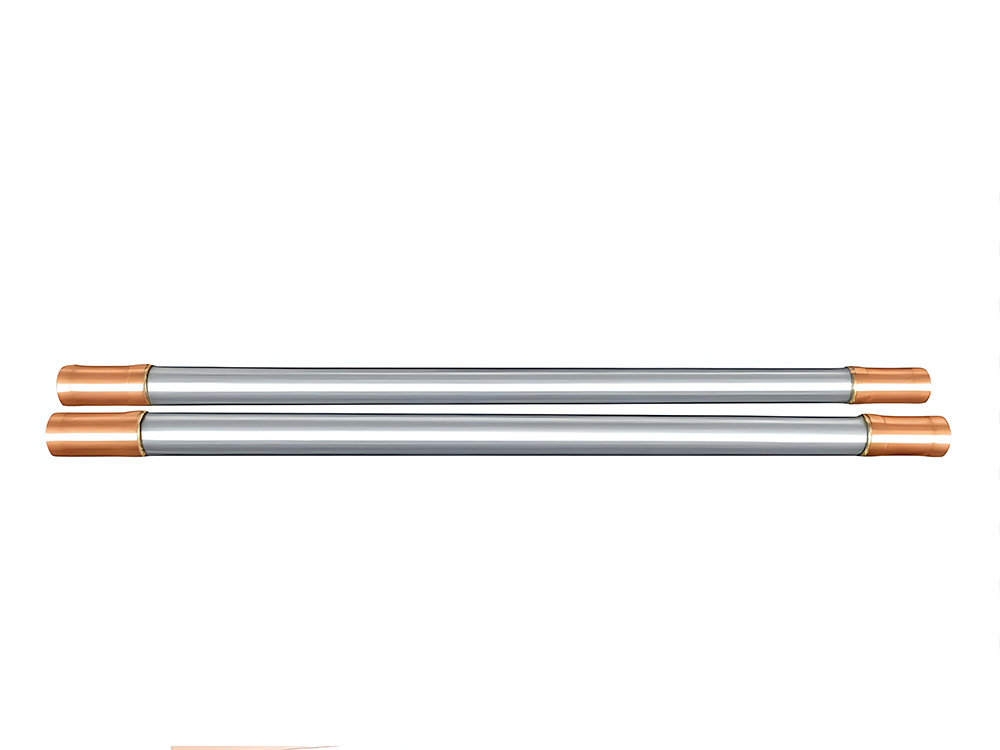

304/316L stainless steel pipe is commonly produced in straight lengths with consistent diameters, designed primarily for fluid transport and pipeline systems. Stainless steel cylinder tube, however, is manufactured with precision for both dimensional accuracy and smooth internal surfaces, making it suitable for applications requiring controlled flow, pressure containment, or integration into mechanical assemblies.

Seamless vs Welded Construction

A significant distinction is the manufacturing method. Stainless steel cylinder tube is typically seamless, ensuring superior mechanical uniformity, while 304/316L stainless steel pipe can be either welded or seamless. Seamless tubes are favored in high-stress or high-pressure scenarios due to reduced susceptibility to leaks or structural weaknesses.

Dimensional and Tolerance Considerations

Precision in dimensions is essential for industrial applications. Stainless steel cylinder tube often adheres to stricter tolerances, supporting critical processes such as refrigeration evaporators, industrial compressors, and chemical reactors. In comparison, 304/316L stainless steel pipe offers a broader range of dimensions and is versatile for general piping networks.

| Feature |

304/316L stainless steel pipe |

Stainless steel cylinder tube |

| Manufacturing |

Welded or seamless |

Mostly seamless |

| Tolerance |

Moderate |

High precision |

| Applications |

Fluid transport, pipelines |

High-pressure systems, mechanical assemblies |

| Surface finish |

Standard |

Smooth internal surface |

Corrosion Resistance and Industrial Suitability

Environmental Factors

316L stainless steel pipe exhibits superior resistance to aggressive chemicals, marine environments, and high-salinity conditions compared to 304 stainless steel. Stainless steel cylinder tube benefits from the same corrosion-resistant properties, making it suitable for industrial refrigeration systems, pharmaceutical processing, and other sectors requiring hygiene and durability.

Maintenance and Longevity

The choice between pipe and tube can also affect maintenance cycles. Stainless steel cylinder tube tends to require less frequent inspection due to its seamless structure, while 304/316L stainless steel pipe may necessitate periodic checks for weld integrity, especially under high-pressure or chemically active environments.

Industrial Applications and Customization

Food Cold Chain and Pharmaceutical Use

In the food cold chain, stainless steel cylinder tube is often integrated into refrigeration units, chillers, and air coolers due to its smooth interior surface, reducing the risk of microbial growth and ensuring efficient heat transfer. 304/316L stainless steel pipe is commonly used in process pipelines, cooling loops, and water distribution systems within these facilities.

Similarly, the pharmaceutical industry relies on stainless steel cylinder tube for precise fluid handling, while 304/316L stainless steel pipe forms the backbone of large-scale cooling and storage systems.

Industrial Process Cooling and Chemical Applications

Industrial refrigeration systems often demand 304/316L stainless steel pipe for extensive network pipelines, while modular cooling units and compressors utilize stainless steel cylinder tube for enhanced durability and system efficiency. These materials support high-pressure, high-temperature, and chemically challenging conditions, allowing engineers to customize system performance according to operational requirements.

Customization and Modular Design

Zhejiang Diya Refrigeration Equipment Co., Ltd. provides expertise in non-standard customization, including structural adjustments, size modifications, refrigerating capacity adaptation, and connection method optimization. Their engineering team applies modular combination design to enhance interchangeability, reduce maintenance costs, and ensure precise integration of 304/316L stainless steel pipe and stainless steel cylinder tube into industrial refrigeration units.

Performance Optimization

Heat Transfer Efficiency

The smooth interior of stainless steel cylinder tube allows for improved heat transfer efficiency, particularly in condensers, chillers, and evaporators. While 304/316L stainless steel pipe provides adequate flow characteristics for general applications, cylinders often outperform in precision cooling systems due to minimized turbulence and enhanced thermal conductivity.

Pressure Handling and Safety

Stainless steel cylinder tube is engineered to withstand higher pressures than standard pipe, making it ideal for compressors, condensing units, and integrated cooling systems. Safety and reliability are critical in industrial applications, and selecting the correct tube or pipe ensures compliance with industry standards and minimizes operational risk.

Industry Standards and Compliance

Certifications and Quality Assurance

Adherence to industry standards is essential for 304/316L stainless steel pipe and stainless steel cylinder tube. Diya's products comply with stringent quality regulations and hold certifications demonstrating their commitment to safety, environmental responsibility, and reliability. Certification provides confidence for buyers in sectors such as food processing, pharmaceuticals, logistics cold chains, and marine refrigeration.

Environmental and Regulatory Considerations

Industrial users must consider local regulations and environmental requirements when selecting materials. 304/316L stainless steel pipe and stainless steel cylinder tube meet strict environmental compliance guidelines, ensuring minimal impact while maintaining optimal performance in diverse operational environments.

Conclusion

Understanding the distinctions between 304/316L stainless steel pipe and stainless steel cylinder tube is critical for selecting the right material for industrial use. Stainless steel cylinder tube offers precision, seamless construction, and superior corrosion resistance, making it ideal for high-pressure, hygienic, and temperature-sensitive applications. 304/316L stainless steel pipe, while versatile and cost-effective, is better suited for general fluid transport and pipeline networks.

With expertise in refrigeration performance customization, modular design, and non-standard structural solutions, companies like Zhejiang Diya Refrigeration Equipment Co., Ltd. provide tailored solutions that integrate both 304/316L stainless steel pipe and stainless steel cylinder tube efficiently into industrial systems. By carefully assessing material properties, application requirements, and environmental conditions, engineers and procurement managers can optimize industrial systems for reliability, performance, and long-term value.

English

English русский

русский Español

Español