How Do Air Cooled Condensing Units Optimize Modern Refrigeration Systems Across Industries?

In today's rapidly evolving refrigeration landscape, air cooled condensing units have emerged as indispensable components in industrial, commercial, and logistics applications. These units not only determine the efficiency of refrigeration systems but also influence operational costs, environmental footprint, and system longevity.

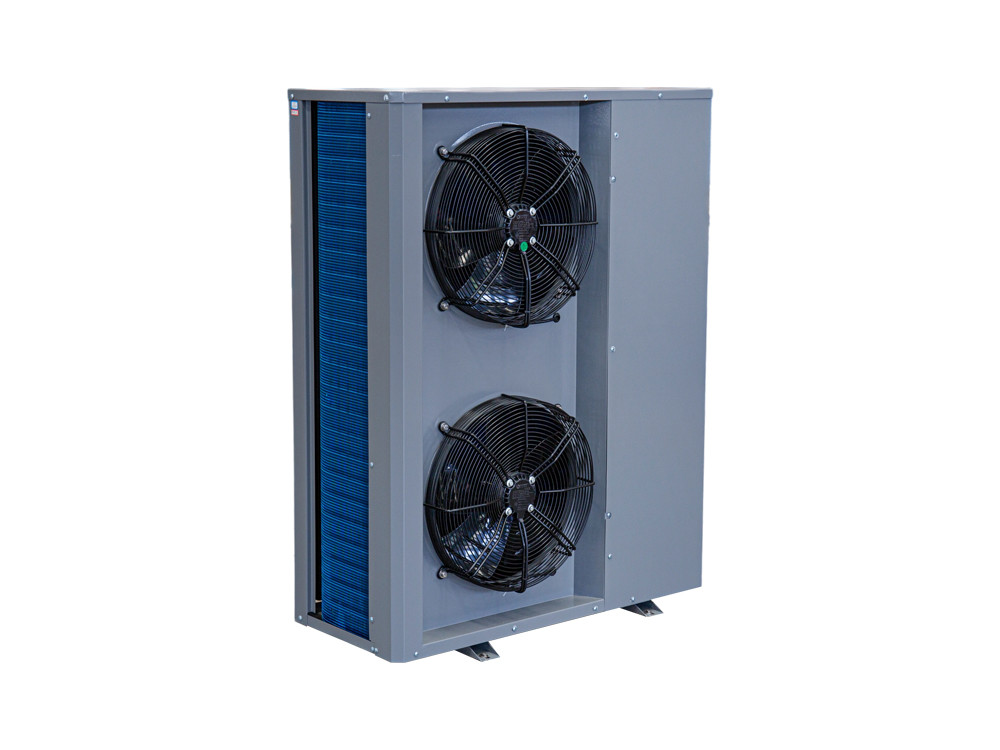

An air cooled condensing unit serves as the heart of a refrigeration system, responsible for dissipating heat absorbed from the evaporator. Unlike water-cooled counterparts, these units utilize ambient air to remove heat, eliminating the need for additional cooling water infrastructure. This design simplifies installation, reduces water dependency, and broadens applicability in regions with limited water resources.

Typically, an air cooled condensing unit integrates compressors, condensers, fans, and controls within a compact structure. The compressor compresses refrigerant vapor, elevating its pressure and temperature. The refrigerant then flows through the condenser coils, where ambient air—forced by high-efficiency fans—removes heat, condensing the vapor into liquid form. The liquid refrigerant proceeds through expansion devices and evaporators, completing the refrigeration cycle. This process highlights the balance between thermodynamic efficiency, mechanical reliability, and airflow optimization, which are central to unit performance.

Key Design Considerations in Industrial Applications

When selecting or designing a box-type condensing unit, several technical factors must be considered to ensure optimal performance and adaptability:

Refrigerating Capacity and Load Matching

Accurate sizing of the condensing unit is essential to match the refrigeration load of the facility. Overcapacity can lead to frequent cycling and energy inefficiency, while undercapacity may compromise cooling performance. Modern solutions employ modular design principles, allowing multiple units to operate in parallel, scaling capacity according to real-time demand.

Thermal and Airflow Optimization

The efficiency of heat transfer is largely determined by condenser coil design and fan placement. High-performance fins and multi-pass coil arrangements can enhance heat dissipation, while variable-speed fans adjust airflow according to ambient conditions, reducing energy consumption and noise levels.

Environmental and Regulatory Compliance

With growing attention to environmental sustainability, selection of refrigerants with low global warming potential (GWP) and adherence to regional standards is critical. Air cooled condensing units are increasingly designed to accommodate eco-friendly refrigerants while maintaining operational efficiency.

Reliability and Maintenance Considerations

Components such as compressors, fans, and controls must offer long-term reliability. Easy accessibility for maintenance, modular component replacement, and durable materials contribute to reduced downtime and lifecycle costs.

Applications Across Industries

Air cooled condensing units have found extensive applications across various sectors due to their versatility:

- Food Cold Chain: Maintaining precise temperature control is crucial for perishable goods. Air cooled condensing units provide consistent cooling, ensuring food safety and quality.

- Industrial Process Cooling: Manufacturing processes, including chemical and pharmaceutical production, require stable refrigeration to protect equipment and maintain product integrity.

- Pharmaceutical Warehousing: Controlled environments for medicines and vaccines depend on reliable cooling units capable of operating in diverse ambient conditions.

- Commercial Refrigeration: Retail and hospitality sectors benefit from compact, efficient units that support freezers, display cabinets, and walk-in coolers.

- Marine and Logistics Cold Chains: Portability and adaptability make box-type condensing units suitable for refrigerated transport and remote storage solutions.

Technological Advancements Driving Efficiency

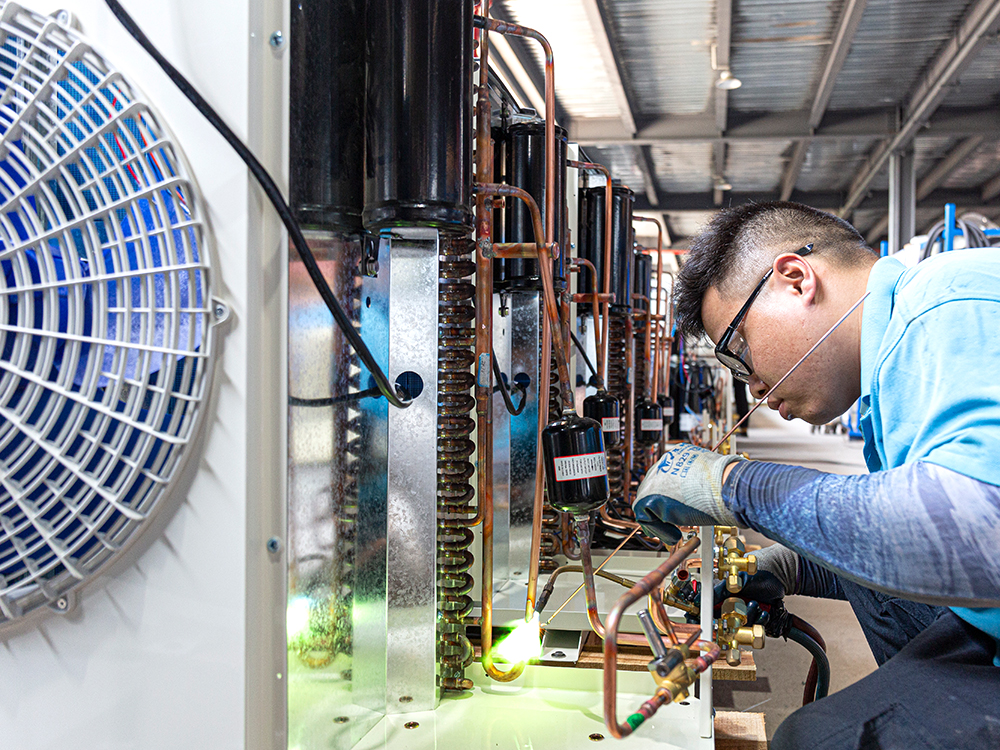

Zhejiang Diya Refrigeration Equipment Co., Ltd. exemplifies innovation in air cooled condensing unit design. With over 40 years of industry experience, Diya has developed more than 10 product series, including air coolers, condensers, screw compressor units, and integrated refrigeration systems. These units are widely deployed in food cold chain, industrial process cooling, pharmaceutical warehousing, commercial refrigeration, marine refrigeration, and logistics cold chain sectors.

Technological highlights include:

- Non-Standard Customization: Diya's engineering team can rapidly adjust structure, size, refrigerating capacity, and connection methods to meet customer-specific requirements.

- Modular Design: Enhances system flexibility, universality, and interchangeability, reducing maintenance costs.

- Advanced Component Integration: Incorporates internationally renowned brands like Bitzer, Copeland, and Hanbell, ensuring efficiency and reliability.

- R&D and Patents: Diya's provincial-level R&D center fosters continuous innovation, providing proprietary solutions to improve energy efficiency and operational stability.

Strategic Benefits of Modern Air Cooled Condensing Units

Energy Efficiency: Modern units employ high-efficiency compressors, optimized condenser coils, and variable-speed fans to minimize energy consumption while maintaining precise cooling.

Scalability: Modular designs allow capacity expansion without major overhauls, making it suitable for growing facilities.

Operational Flexibility: Units can operate in diverse climates, with adjustable parameters to handle fluctuating loads and ambient temperatures.

Maintenance and Lifecycle Cost Reduction: Easy-to-access components, standardized parts, and robust construction reduce downtime and total cost of ownership.

Environmental Responsibility: Support for eco-friendly refrigerants and optimized airflow contributes to lower carbon emissions and regulatory compliance.

Quality Assurance and Certification

Zhejiang Diya Refrigeration Equipment Co., Ltd. 's box-type condensing units have achieved multiple certifications, including ISO9001, CE, and RACC, reflecting adherence to international quality standards. Rigorous testing protocols, combined with the selection of high-quality core components, ensure stable operation under diverse conditions. This focus on certified quality underlines the commitment to delivering reliable, high-performance refrigeration solutions globally.

Conclusion

Air cooled condensing units are at the forefront of modern refrigeration technology, offering efficiency, adaptability, and reliability across multiple industries. From cold chain logistics to pharmaceutical storage, these units address critical cooling challenges while enabling operational flexibility and environmental compliance.

English

English русский

русский Español

Español