What Makes All-in-One Condensing Units Essential for Commercial and Industrial Cooling Projects?

The evolution of refrigeration technology has significantly transformed industrial, commercial, and cold chain operations, driving demand for compact, efficient, and versatile solutions. Among these, the all-in-one condensing unit has emerged as a crucial component in modern refrigeration systems, combining high performance, modularity, and user-friendly design. Its integration of compressors, condensers, expansion devices, and control systems into a single unit allows for streamlined installation, reduced maintenance, and reliable operation across various applications.

Concept and Structure of All-in-One Condensing Units

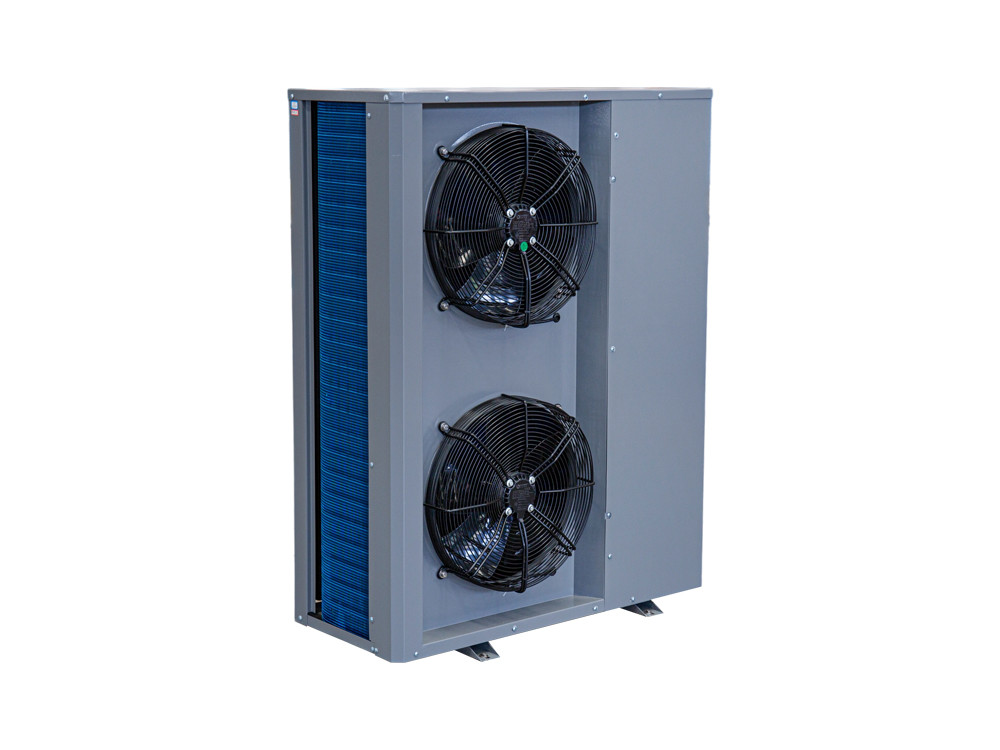

An all-in-one condensing unit integrates essential refrigeration components within a single framework. Typically, these components include a hermetic or semi-hermetic compressor, air-cooled or water-cooled condenser, expansion device, and a control system. This integration simplifies installation by reducing the need for complex piping, external connections, and extensive site assembly.

The unit's design emphasizes compactness and accessibility. Structural optimization ensures efficient airflow over the condenser, minimizes energy losses, and allows for easy maintenance. Modular design principles are increasingly applied, enabling flexible combinations of cooling capacity, connection types, and component specifications to cater to varying industrial requirements.

High-performance units are often equipped with scroll or screw compressors, which provide high efficiency, low noise, and consistent refrigerating capacity. Air-cooled condensers dominate commercial applications due to their ease of installation, whereas water-cooled variants are preferred in industrial settings where space and heat rejection management are critical.

Key Advantages of All-in-One Condensing Units

Space Efficiency and Simplified Installation

Unlike conventional split systems that require separate compressors and condensers, an all-in-one condensing unit consolidates multiple components into a single frame. This reduces footprint requirements and shortens installation time. For facilities such as warehouses, supermarkets, and industrial plants, this translates to lower labor costs and faster project turnaround.

Reliable and Consistent Performance

All-in-one condensing units provide stable operation across diverse conditions. Integration ensures that component sizing and performance are optimized as a complete system, reducing the risk of inefficiencies or operational conflicts. Additionally, advanced control systems manage refrigerant flow, pressure, and temperature, enhancing system stability and energy efficiency.

Flexibility and Customization

Different applications require tailored solutions. Zhejiang Diya Refrigeration Equipment Co., Ltd. has leveraged over 40 years of industry expertise to offer non-standard customization, enabling adjustments in structure, refrigerating capacity, and connection methods. This flexibility ensures that each all-in-one condensing unit aligns with specific industrial processes, cold storage requirements, or commercial refrigeration demands.

Maintenance and Operational Convenience

Modular design enhances interchangeability of components, simplifying maintenance and reducing downtime. Easily accessible parts allow technicians to conduct routine checks, replacements, or upgrades without dismantling the entire system. This reliability is crucial for cold chain operations, food storage, and pharmaceutical warehousing, where temperature stability is paramount.

Applications Across Industries

Food Cold Chain and Logistics

All-in-one condensing units are extensively used in cold storage and logistics, ensuring consistent temperature control for perishable goods. Their compact design and efficiency make them ideal for urban warehouses or transportation hubs with limited space.

Industrial Process Cooling

Many industrial processes generate heat requiring precise and continuous cooling. All-in-one units deliver reliable refrigeration for chemical production, electronics manufacturing, and metal processing, where precise temperature management enhances product quality and energy efficiency.

Commercial Refrigeration

Supermarkets, restaurants, and convenience stores benefit from the simplified installation, reduced footprint, and energy-efficient operation of all-in-one units. Diya's units can integrate seamlessly with display cabinets, cold rooms, and ice-making systems.

Pharmaceutical and Healthcare Storage

Temperature-sensitive pharmaceuticals demand stable cooling conditions. All-in-one condensing units with precise controls and redundant safety systems ensure the integrity of vaccines, biologics, and other critical products throughout storage and transport.

Marine and Specialized Applications

Marine refrigeration and offshore installations often face space and environmental constraints. The compact and robust design of all-in-one condensing units meets these requirements, providing reliable cooling under challenging conditions.

Technological Features and Innovations

Advanced Compressor Technology

Diya integrates screw and scroll compressors with high volumetric efficiency, optimized for varying load conditions. These compressors provide smooth operation, minimal vibration, and energy savings while supporting modular configurations.

Intelligent Control Systems

Modern all-in-one condensing units include digital control systems capable of monitoring and adjusting temperature, pressure, and flow rates. Such systems also support remote diagnostics and predictive maintenance, improving operational reliability.

Energy Efficiency and Sustainability

Efficient heat exchange, low-pressure loss designs, and variable-speed compressors enhance energy performance. Additionally, compatibility with environmentally friendly refrigerants aligns with global trends toward sustainable refrigeration solutions.

Standardization and Modular Design

By promoting modularity, Diya enhances universality and interchangeability. Standardized modules allow quick replacement, expansion, or integration with other refrigeration components, reducing lifecycle costs and facilitating scalability.

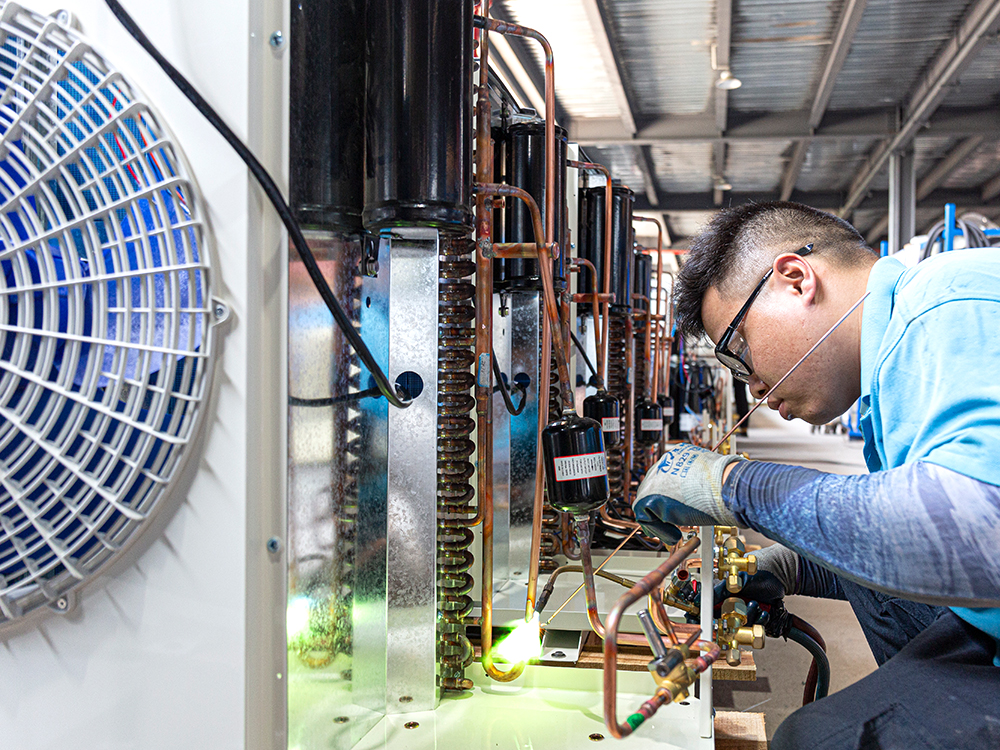

Quality Assurance and Compliance

Zhejiang Diya Refrigeration Equipment Co., Ltd. ensures that all products meet rigorous quality standards. Core components are sourced from internationally recognized brands, and the company maintains certifications such as ISO9001, CE, and RACC. Each all-in-one condensing unit undergoes strict testing for performance, durability, and safety, ensuring dependable operation across industries.

Industry Expertise and Support

With over four decades of experience, Diya offers comprehensive technical support, from project consultation to after-sales service. Their engineering team, skilled in mechanical engineering, thermodynamics, and structural optimization, delivers professional guidance on selecting and customizing units. This expertise ensures that clients receive tailored solutions for specific refrigeration challenges.

Conclusion

In conclusion, the all-in-one condensing unit represents a versatile and efficient solution for modern refrigeration needs. Its integration of compressors, condensers, and controls into a compact, modular unit offers space savings, operational reliability, and flexible customization.

English

English русский

русский Español

Español