Air Cooled Condenser Industry Knowledge: Selection, Application & Innovation

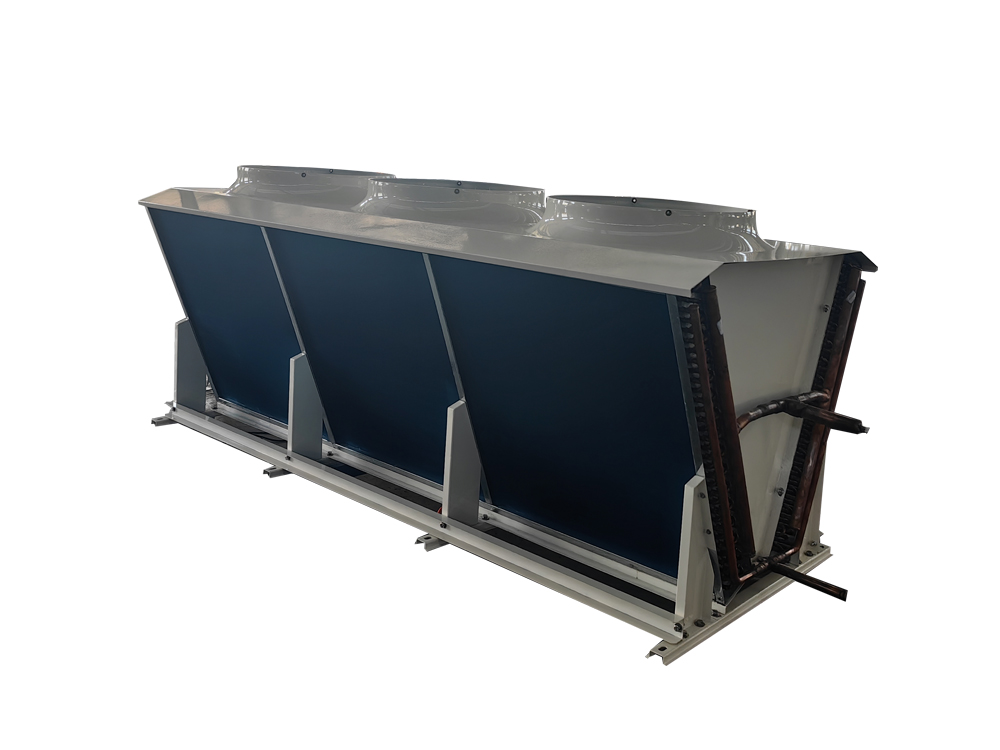

As a core component in refrigeration and air conditioning systems, the Air Cooled Condenser plays a vital role in system efficiency and reliability. Understanding its technical nuances is key to optimal project success. Below, we explore critical aspects of Air Cooled Condensers, integrating the expertise and manufacturing excellence of Zhejiang Diya Refrigeration Equipment Co., Ltd., a trusted name since 1983.

1. How to Choose the Right Air Cooled Condenser for Your Project? 5 Key Parameters Explained

Selecting the correct Air Cooled Condenser is fundamental to system performance. Based on over 40 years of manufacturing experience at Zhejiang Diya, we recommend focusing on these five critical parameters:

- Heat Rejection Capacity: Measured in kW or RT (Refrigeration Tons), this is the core performance indicator, requiring precise calculation based on your system's cooling load.

- Fan Power and Quantity: Directly impacts cooling airflow and operational noise, significantly influencing energy consumption.

- Design Pressure: Specified for the refrigerant side (e.g., for R410A, R407C) and the shell, ensuring safe operation under high pressure.

- Coil Design: Includes tube material (like inner-grooved copper), fin type (hydrophilic aluminum), and circuit rows, which determine heat transfer efficiency and corrosion resistance.

- Physical Dimensions and Connections: Ensures the unit fits the allocated space and that pipe connections are compatible.

As an ISO9001 and CE-certified enterprise, Diya's engineering team provides expert selection support tailored to your specific application—from the high ambient temperatures of the Middle East to the temperate climates of Europe—ensuring optimal performance.

2. Air-Cooled vs. Water-Cooled: Why Air Cooled Condensers are the Preferred Choice for Water-Scarce and Easy-Maintenance Scenarios

The choice between air-cooled and water-cooled condensers is critical. Air Cooled Condensers excel by eliminating dependency on cooling water systems, making them ideal for regions with water scarcity or hard water issues (e.g., markets in the Middle East and parts of Africa).

Key Comparative Parameters/Advantages:

- Water Consumption: 0 tons (Air-Cooled) vs. Significant circulating water (Water-Cooled + Cooling Tower).

- System Overall Efficiency: In arid regions, the overall efficiency and maintenance costs of air-cooled systems often outperform water-cooled systems plagued by scaling issues.

- Installation Space Requirements: Air-cooled units require good ventilation but save space by eliminating cooling towers and pump rooms.

- Maintenance Costs: Primary maintenance involves coil cleaning and fan inspection, avoiding problems like scale and algae common in water systems.

With products exported worldwide, Zhejiang Diya understands diverse environmental challenges. Our Air Cooled Condensers are engineered to deliver reliable performance in harsh conditions, minimizing long-term maintenance for our clients.

3. Enhancing Efficiency & Lifespan: The 3 Design Philosophies Behind Zhejiang Diya's Air Cooled Condensers

Since its establishment in 1983, Zhejiang Diya has embedded "Durability and Efficiency" into its product DNA. Our Air Cooled Condensers are popular in demanding markets like Europe and America due to three core design philosophies:

- Optimized Heat Exchange Technology: Utilizing inner-grooved copper tubes and enhanced fin design to significantly increase the heat transfer area and improve thermal efficiency, achieving a higher heat rejection capacity</strong within a compact footprint.

- Superior Weather Resistance & Anti-Corrosion: For specific export environments (e.g., humid Southeast Asia, salty coastal air), we offer options like epoxy resin coatings or electrophoretic coating on fins to substantially extend coil life.

- High-Efficiency, Low-Noise Fan System: Employing quality fans and motors with CFD-optimized airflow design ensures sufficient cooling airflow while effectively controlling operational noise, meeting environmental and community standards.

Our in-house factory and strict ISO9001 quality control ensure every condenser that leaves our facility meets these high design standards.

4. From Factory to Global: Analyzing the Rigorous Testing Process for Zhejiang Diya's Air Cooled Condensers

A reliable Air Cooled Condenser must pass rigorous tests before shipment. As a large modern enterprise integrating R&D, manufacturing, sales, and service, Zhejiang Diya implements a meticulous testing protocol to guarantee product reliability for its global journey.

Core Testing Parameters & Stages:

- Pressure Hold Test: The completed condenser coil is charged with high-pressure dry nitrogen (exceeding design pressure) and held for hours to ensure zero leakage.

- Performance Run Test: Under simulated operating conditions, key parameters like heat rejection capacity, fan amperage, and air temperature differential are verified against design standards.

- Electrical Safety Test: Fan motors and terminals undergo insulation resistance and high-potential (hipot) tests to ensure electrical safety, a prerequisite for CE certification.

- Final Visual & Cleanliness Inspection: Ensures the unit is free from shipping damage and internal contaminants, guaranteeing a clean system.

This stringent quality control system allows our products to be confidently exported to high-standard markets like Europe and America, earning long-term customer trust.

5. Beyond Standard: How Zhejiang Diya Customizes Air Cooled Condenser Solutions for Special Industries

Standard products can't meet every need. A core strength of Zhejiang Diya is its robust R&D and customization capability, providing tailor-made air-cooled condenser solutions for specialized industries like chemicals, pharmaceuticals, and food processing.

Customization Parameters & Solution Examples:

- Material Upgrade: For corrosive environments, we offer options like stainless steel coils or marine-grade aluminum alloy fins.

- Explosion-Proof Design: For hazardous areas in chemical plants, we integrate certified explosion-proof fans and motors.

- Non-Standard Dimensions & Layout: We customize the footprint or fan arrangement (e.g., top airflow, horizontal airflow) to fit limited spaces.

- High-Ambient-Temperature Design: For regions like the Middle East, we enhance performance by increasing the heat exchange area or adjusting fan configuration to ensure stable operation at ambient temperatures up to 55°C.

Our engineering team embraces challenges, working closely with clients to translate requirements into practical engineering solutions. This perfectly embodies our integrated business model of "R&D, design, manufacturing, and engineering installation."

English

English русский

русский Español

Español