Understanding the Role of Cold Room Evaporators in Efficient Refrigeration Systems

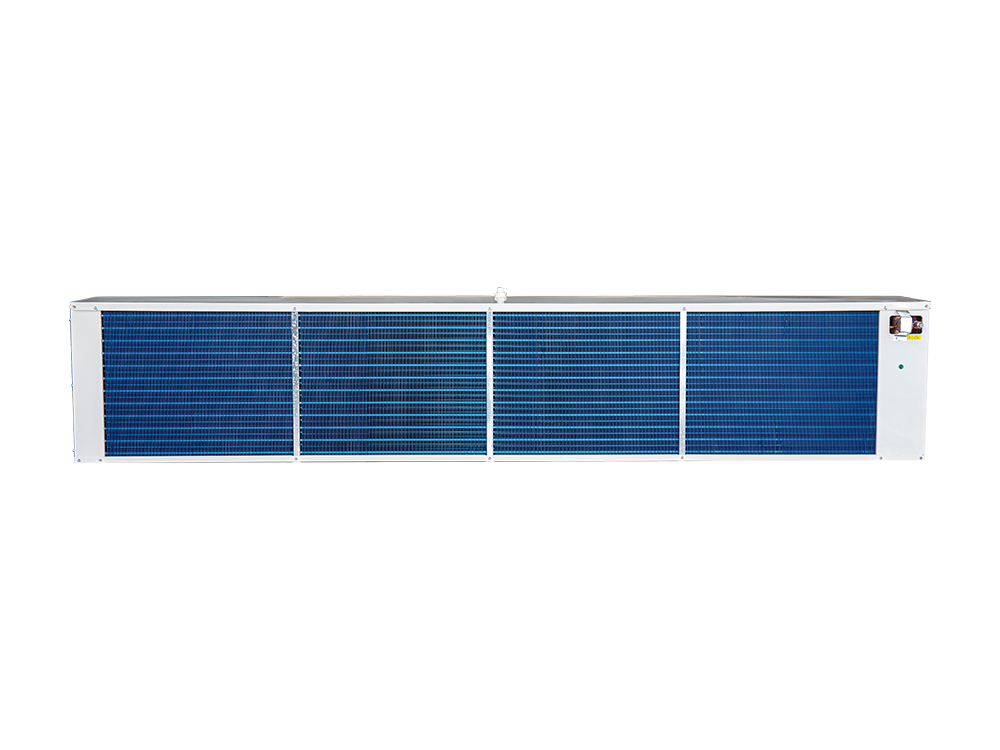

A cold room evaporator is a crucial component in refrigeration systems, particularly in commercial and industrial cold storage environments. Its main function is to absorb heat from the air inside the cold room and transfer it to the refrigerant, enabling the room to maintain the desired low temperature efficiently.

1. Heat Absorption and Refrigerant Cycle

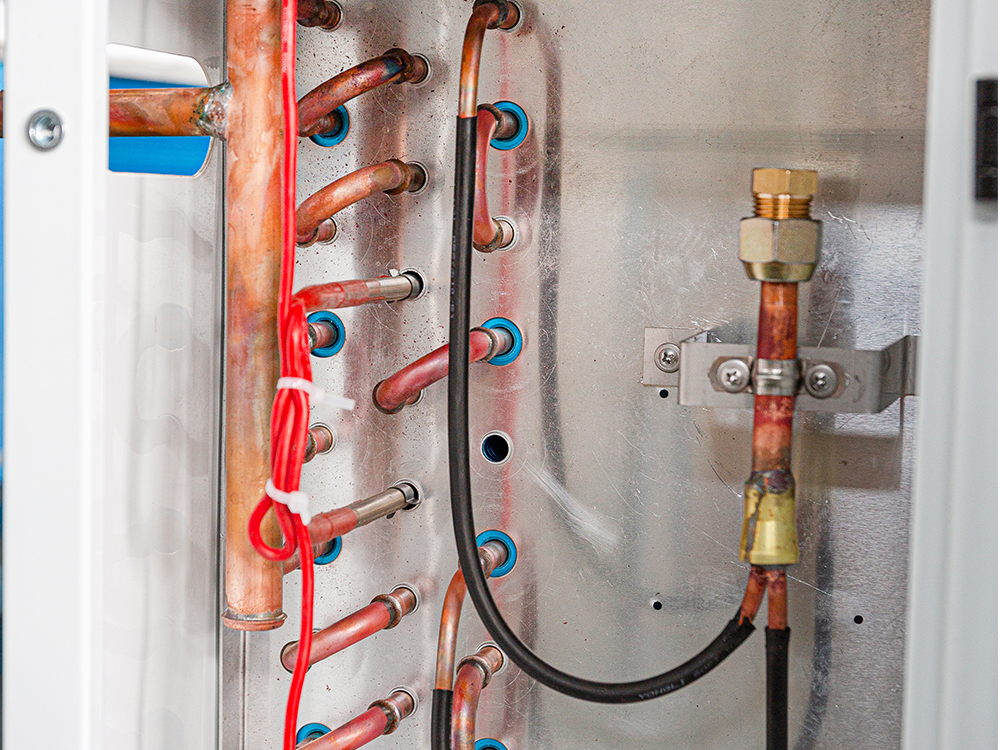

The evaporator works as part of the refrigeration cycle. Refrigerant enters the evaporator as a low-pressure liquid and absorbs heat from the cold room air, causing it to evaporate into a gas. This process removes heat from the stored goods, keeping them at a safe temperature. The gaseous refrigerant then moves to the compressor, continuing the cooling cycle.

2. Air Distribution and Temperature Uniformity

Many cold room evaporators are equipped with fans that circulate air evenly across the room. Proper air circulation ensures that temperature remains uniform, preventing hot spots that could spoil perishable items.

3. Energy Efficiency

Modern cold room evaporators are designed to be energy-efficient. Features like optimized fin design, variable-speed fans, and proper sizing reduce energy consumption while maintaining cooling performance. An efficiently running evaporator helps reduce overall operating costs of refrigeration systems.

4. Humidity Control

Evaporators also play a role in humidity management. By removing moisture from the air during heat exchange, they help maintain an ideal storage environment for products sensitive to humidity, such as fruits, vegetables, and pharmaceuticals.

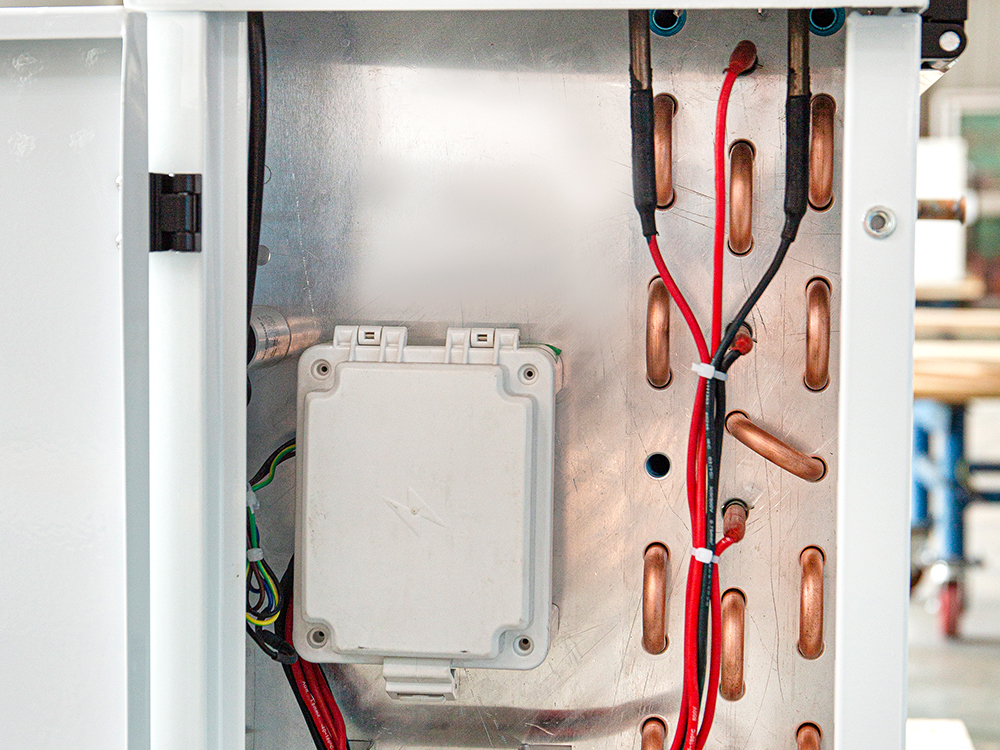

5. Maintenance and Longevity

Regular maintenance—such as cleaning coils, checking fan motors, and monitoring refrigerant levels—is essential. A well-maintained evaporator operates efficiently, prolongs equipment life, and minimizes the risk of unexpected breakdowns.

The cold room evaporator is the heart of an efficient refrigeration system. Its proper design, operation, and maintenance ensure consistent cooling, energy savings, and protection of stored products.

Common Issues in Cold Storage Evaporators and How to Troubleshoot Them

Cold storage evaporators are critical components in refrigeration systems, responsible for removing heat from the storage area and maintaining low temperatures. Despite their reliability, they can experience common issues that affect performance. Understanding these problems and their solutions is essential for maintaining an efficient cold storage operation.

1. Frost or Ice Buildup on Evaporator Coils

Cause:

- Excess moisture in the storage area

- Malfunctioning defrost system

- Poor airflow due to blocked fans

Troubleshooting:

- Inspect and clear any obstructions around the evaporator

- Check defrost heater and timer for proper operation

- Ensure the humidity in the cold storage is within recommended levels

2. Inadequate Cooling or Temperature Fluctuations

Cause:

- Low refrigerant charge

- Faulty expansion valve

- Airflow issues from fan malfunction or dirty coils

Troubleshooting:

- Measure refrigerant pressure and recharge if necessary

- Test and replace the expansion valve if defective

- Clean evaporator coils and verify that fans are operating correctly

3. Unusual Noises

Cause:

- Loose fan blades or motor components

- Refrigerant flow issues causing vibration

- Ice accumulation hitting the fan

Troubleshooting:

- Tighten any loose components

- Check refrigerant lines for proper installation and flow

- Remove ice and ensure proper defrost cycles

4. Water Leaks Around the Evaporator

Cause:

- Clogged or damaged drain lines

- Improper defrost drainage

- Excess condensation due to high humidity

Troubleshooting:

- Inspect and clean drain pans and drain lines

- Adjust defrost cycle timing

- Maintain humidity control in the storage area

5. Reduced Airflow Across Evaporator Coils

Cause:

- Dust, dirt, or frost buildup on coils

- Faulty fans or motors

- Obstructions in the ductwork

Troubleshooting:

- Clean evaporator coils regularly

- Test fan motors and replace if necessary

- Remove blockages and ensure proper airflow paths

Summary

Regular maintenance, including coil cleaning, fan inspection, defrost system checks, and humidity control, is crucial to prevent common issues in cold storage evaporators. Prompt troubleshooting not only restores efficiency but also extends the life of the equipment.

English

English русский

русский Español

Español