How Electric Defrosting Air Coolers Improve Energy Efficiency in Cold Storage Systems

Electric defrosting air coolers are widely used in cold storage and refrigeration systems to maintain optimal temperatures while minimizing energy consumption. Their energy efficiency benefits stem from several key factors:

1. Precise Defrost Control

Electric defrosting systems use controlled electric heaters to remove frost or ice buildup on the evaporator coils. Unlike manual or hot-gas defrosting, electric defrost cycles can be scheduled or triggered automatically based on coil temperature and frost accumulation. This precision ensures that defrosting occurs only when necessary, reducing unnecessary energy usage.

2. Reduced Compressor Load

Frost accumulation on the evaporator coil acts as an insulating layer, reducing heat transfer efficiency. Electric defrosting quickly restores the coil’s efficiency, allowing the refrigeration system to maintain target temperatures with less work from the compressor, which is one of the highest energy-consuming components in a cold storage system.

3. Optimized Airflow

By keeping the evaporator coils frost-free, electric defrosting ensures consistent airflow throughout the storage space. Good airflow reduces temperature stratification, helping the system maintain uniform cooling without overcooling, which further reduces energy consumption.

4. Shorter Defrost Cycles

Electric defrosting air coolers typically have shorter and more efficient defrost cycles compared to hot-gas or water defrost systems. Shorter defrost periods minimize the time the refrigeration system needs to work harder to compensate for lost cooling, saving energy.

5. Integration with Energy Management Systems

Modern electric defrosting air coolers can be integrated with smart controllers and IoT-enabled energy management systems, which optimize defrost schedules based on usage patterns, ambient conditions, and real-time monitoring. This integration further improves overall energy efficiency and reduces operational costs.

6. Lower Heat Loss

Electric defrosting does not require introducing additional heat into the cold storage space like hot gas or water methods, meaning less heat is added to the environment, which in turn reduces the energy needed to re-cool the space after defrosting.

Electric defrosting air coolers improve energy efficiency by precisely controlling defrost cycles, reducing compressor workload, maintaining optimal airflow, shortening defrost times, and integrating with smart energy systems. These advantages make them an ideal choice for modern cold storage systems where energy savings and operational reliability are critical.

Comparing Electric Defrosting and Hot Gas Defrosting Air Coolers: Pros and Cons

Air coolers in refrigeration systems require periodic defrosting to maintain efficiency. Two commonly used methods are electric defrosting and hot gas defrosting. Choosing the right type depends on application, energy efficiency, maintenance requirements, and system design.

1. Overview of Defrosting Methods

Electric Defrosting Air Coolers use controlled electric heaters to melt frost on the evaporator coils. The defrost cycle is typically programmable or sensor-driven.

Hot Gas Defrosting Air Coolers redirect hot refrigerant gas from the compressor to the evaporator to remove frost. This method is widely used in industrial refrigeration.

2. Pros and Cons Comparison

| Feature |

Electric Defrosting Air Cooler |

Hot Gas Defrosting Air Cooler |

| Energy Efficiency |

Moderate; defrost cycles are controlled and short, reducing energy waste |

Can be less energy-efficient as hot gas requires extra compressor work |

| Installation Complexity |

Simple; requires only electrical connections |

More complex; needs additional piping and valves for hot gas routing |

| Maintenance |

Easy; fewer mechanical components and lower risk of leaks |

Higher; valves and piping require periodic inspection and maintenance |

| Defrost Speed |

Slower than hot gas; may take longer for thick frost layers |

Faster; suitable for large frost loads and high-capacity systems |

| System Integration |

Easy to integrate with small-to-medium cold storage systems |

Best for industrial or large-scale refrigeration where fast defrost is critical |

| Initial Cost |

Lower upfront cost |

Higher due to additional components |

| Operational Noise |

Low; minimal impact on system operation |

Slightly higher due to hot gas flow and compressor activity |

3. Application Recommendations

Electric defrosting air coolers are ideal for medium-sized cold storage, commercial refrigeration, or applications where precise energy control is important.

Hot gas defrosting air coolers are preferred for large industrial refrigeration systems, food processing plants, and scenarios with high frost accumulation.

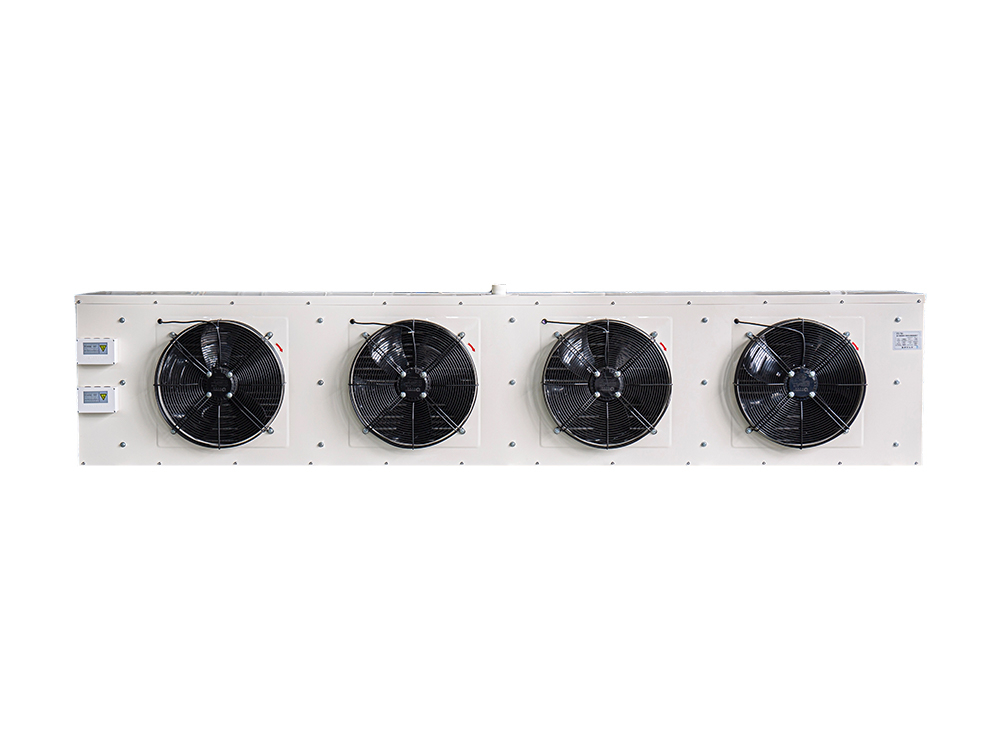

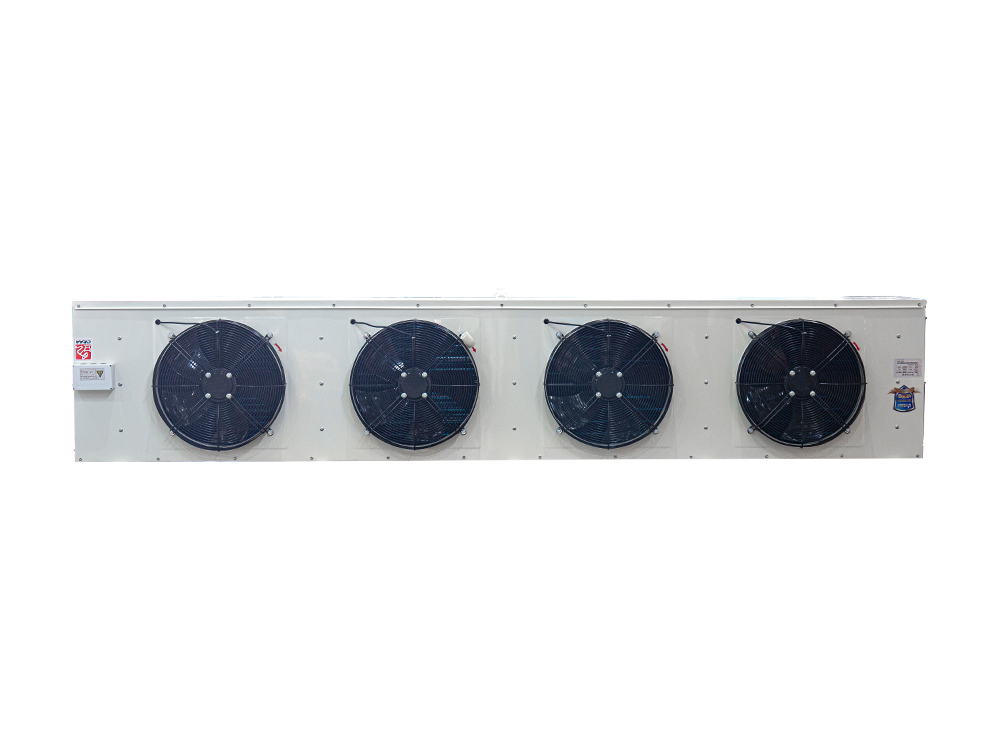

4. About the Company

Zhejiang Diya Refrigeration Equipment Co., Ltd., founded in 1983 and headquartered in Huzhou, Zhejiang Province, is a modern comprehensive enterprise integrating R&D, manufacturing, sales, engineering installation, and after-sales service. Covering 134,000 square meters with more than 260 employees, including over 38 technical and management backbones, Diya has built a complete industrial refrigeration product system. Its products, including air coolers, condensers, screw compressor units, chillers, and integrated systems, are widely used in food cold chain, industrial process cooling, pharmaceutical warehousing, commercial refrigeration, marine refrigeration, and logistics cold chain industries.

The company emphasizes quality and customer satisfaction with the corporate philosophy of "integrity first, management first, people-oriented, striving for excellence", making it a trustworthy Chinese brand in global industrial refrigeration.

English

English русский

русский Español

Español