What are the differences between seamless and welded stainless steel straight pipe for buyers?

When selecting stainless steel straight pipe for industrial or commercial applications, buyers often encounter two primary types: seamless and welded. Understanding their differences is crucial to ensure proper performance, durability, and cost-effectiveness. The choice between these options is influenced by the application environment, mechanical requirements, and production considerations.

Stainless steel straight pipe is widely used in industries such as refrigeration, food processing, pharmaceuticals, logistics cold chain, and marine systems. Companies like Zhejiang Diya Refrigeration Equipment Co., Ltd. demonstrate how customization, modular design, and performance optimization can complement the use of high-quality pipe materials in specialized industrial systems.

Understanding Seamless Stainless Steel Straight Pipe

Definition and Production

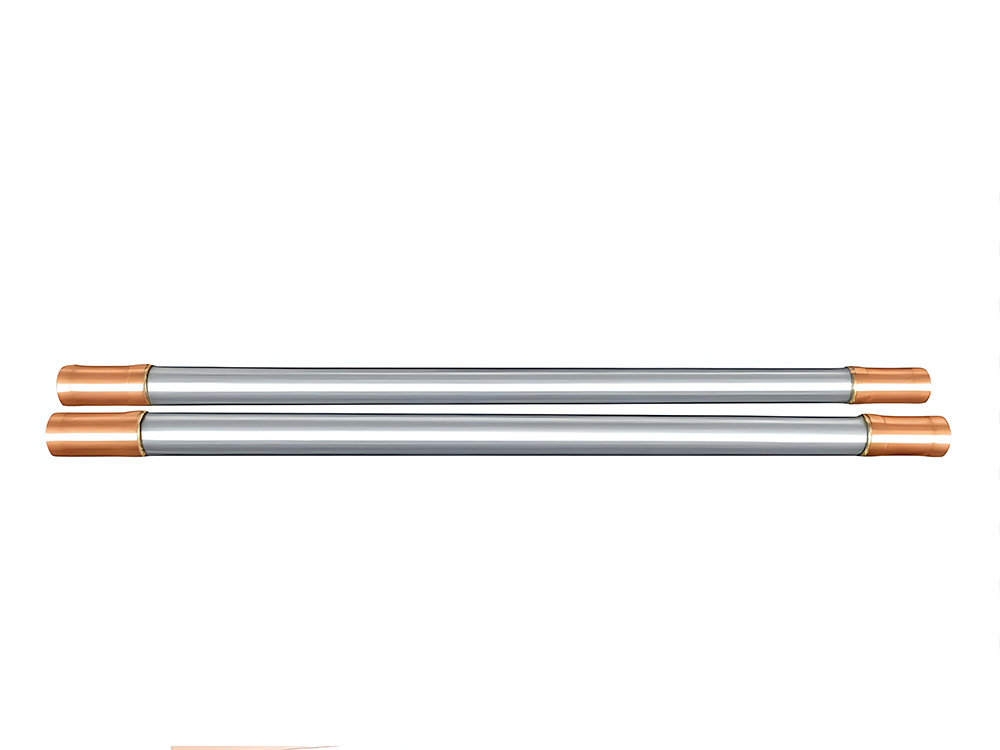

Seamless stainless steel straight pipe is manufactured through extrusion or hot rolling, without any welded seams. This results in a uniform structure throughout the pipe, eliminating weak points associated with welding lines. The seamless process ensures higher pressure resistance and superior mechanical properties, making it ideal for demanding applications.

Key Features

- Structural Integrity: The absence of a weld seam ensures that the pipe is resistant to internal and external pressures.

- Corrosion Resistance: Seamless pipes have a consistent microstructure, which enhances resistance to rust and chemical exposure.

- Durability and Longevity: Seamless pipes generally have a longer lifespan under high-stress conditions, such as elevated temperature and high-pressure systems.

Common Applications

Seamless stainless steel straight pipe is typically used in:

- High-pressure refrigeration pipelines

- Pharmaceutical and chemical process systems

- Marine and food cold chain systems

- Industrial equipment requiring structural reliability

This type of pipe is preferred when safety and performance are critical, and the environment is subject to fluctuating temperatures or corrosive substances.

Understanding Welded Stainless Steel Straight Pipe

Definition and Production

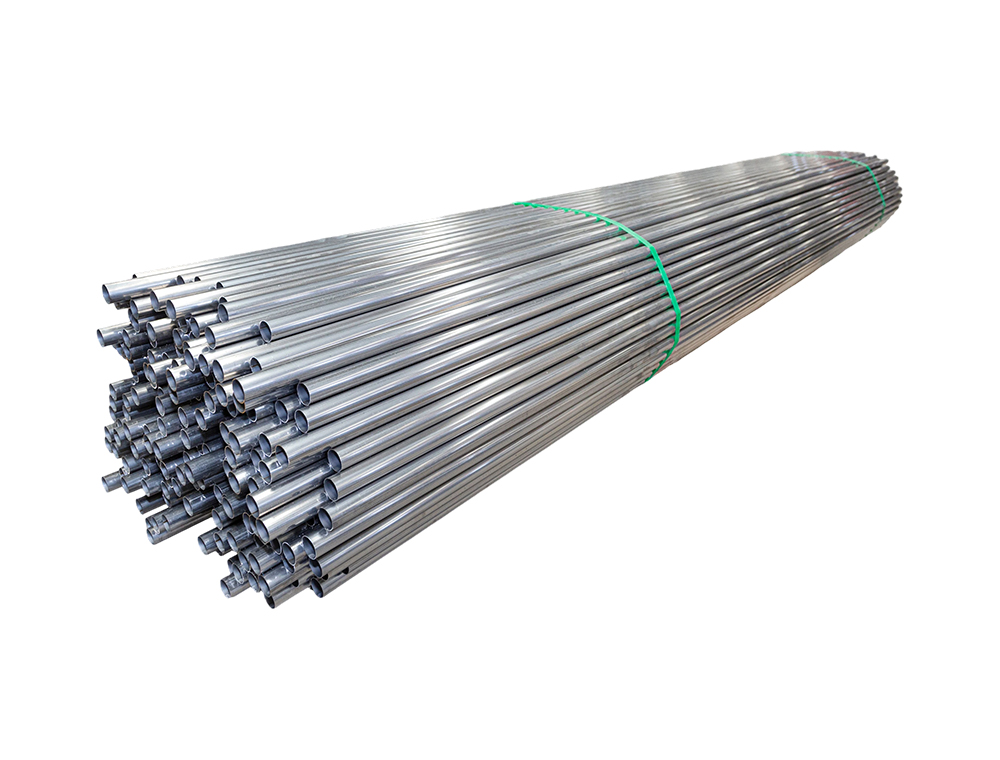

Welded stainless steel straight pipe is produced by rolling a flat strip of steel into a cylindrical shape and joining the edges through welding. Advanced welding techniques ensure strong seams, though the welded area may exhibit slightly different mechanical properties than the base metal.

Key Features

- Cost-Effectiveness: Welded pipes are generally less expensive than seamless options due to simplified production methods.

- Availability: They are widely available in various diameters and wall thicknesses, making them suitable for many standard applications.

- Versatility: Welded pipes can be easily customized for size and length, supporting modular design in industrial systems.

Common Applications

Welded stainless steel straight pipe is suitable for:

- Low to medium-pressure refrigeration systems

- Air and water cooling networks

- Modular industrial equipment pipelines

- General industrial applications where extreme pressure or corrosion resistance is not the primary concern

Comparing Seamless and Welded Stainless Steel Straight Pipe

| Feature |

Seamless Stainless Steel Straight Pipe |

Welded Stainless Steel Straight Pipe |

| Production Method |

Extrusion or hot rolling without seams |

Rolling and welding of steel strips |

| Structural Integrity |

High, no weak points |

Moderate, welded seam may be less resistant |

| Pressure Resistance |

Excellent |

Good, suitable for standard applications |

| Corrosion Resistance |

Superior due to uniform structure |

Slightly lower at the welded joint |

| Cost |

Higher due to complex manufacturing |

Lower, more economical for large-scale use |

| Customization |

Limited in diameter and length |

High flexibility in size and shape |

| Typical Industries |

High-pressure refrigeration, pharmaceuticals, marine |

General refrigeration, water/air cooling, industrial pipelines |

Understanding these differences allows buyers to select the most appropriate pipe for their specific industrial environment and budget.

Factors Buyers Should Consider

1. Application Environment

The choice between seamless and welded stainless steel straight pipe depends heavily on the operational environment. For high-pressure or corrosive systems, seamless pipes offer superior performance. In contrast, welded pipes are suitable for moderate pressure and standard industrial settings.

2. Cost Efficiency

While seamless pipes provide better durability and performance, welded pipes offer a cost-effective solution for large-scale installations, especially when modular design is employed.

3. Compatibility with Equipment

Buyers should ensure the pipe matches industrial system requirements, such as diameter, connection type, and compatibility with compressors or condensers in refrigeration systems. Companies like Zhejiang Diya Refrigeration Equipment Co., Ltd. illustrate the importance of customized solutions, adjusting pipe parameters for optimal system integration.

4. Maintenance Considerations

Seamless pipes generally require less maintenance due to uniform structural integrity, whereas welded pipes may need additional inspections around the weld seam in high-stress applications.

5. Compliance and Standards

Both types of pipes must comply with industry standards, including pressure ratings, corrosion resistance, and material certifications. Adhering to recognized quality standards ensures safety and operational reliability.

Role of Customization in Industrial Applications

Companies in industrial refrigeration, logistics cold chain, and other demanding sectors benefit from tailored pipe solutions. Stainless steel straight pipe can be incorporated into systems with:

- Non-standard structural designs for unique pipelines

- Modular combination designs to enhance interchangeability

- Customized refrigerating capacity adjustments to match operational needs

Zhejiang Diya Refrigeration Equipment Co., Ltd. emphasizes a customer demand-oriented approach, demonstrating that tailored pipe integration is critical for performance optimization in diverse industrial scenarios.

Practical Considerations for Buyers

Material Selection

Selecting the right stainless steel grade (e.g., 304, 316) affects corrosion resistance, temperature tolerance, and compatibility with refrigerants or other fluids.

Pipe Size and Wall Thickness

Determining the correct diameter and wall thickness ensures optimal fluid flow and system pressure management. Buyers should evaluate system requirements before making a purchase.

Connection Methods

Both seamless and welded pipes support various connections, including flanges, threaded joints, or butt welds. Correct connection type minimizes leaks and maximizes system efficiency.

Inspection and Testing

Routine inspection ensures mechanical integrity, especially for welded pipes. Visual inspection, pressure testing, and compliance verification maintain system reliability.

Industry Trends and Buyer Considerations

The stainless steel pipe industry continues to evolve with:

- Increasing adoption of modular and non-standard designs

- Emphasis on environmental responsibility and compliance with local regulations

- Rising demand in food cold chain, industrial cooling, and pharmaceutical sectors

Buyers should stay informed about industry trends to select pipes that meet long-term operational and regulatory requirements.

Conclusion

For buyers, understanding the differences between seamless and welded stainless steel straight pipe is critical for selecting the right product. Seamless pipes offer high pressure resistance, corrosion resistance, and durability, making them ideal for demanding industrial applications. Welded pipes, however, provide flexibility, customization, and cost efficiency, suitable for standard refrigeration and industrial systems.

Integrating these pipes into industrial systems, as demonstrated by companies like Zhejiang Diya Refrigeration Equipment Co., Ltd., requires careful consideration of material grade, system compatibility, and operational requirements. By evaluating these factors, buyers can ensure both performance and cost-effectiveness while meeting industry standards.

English

English русский

русский Español

Español