What are the key differences between a standard and custom-built V-type box condensing unit?

The V-type box condensing unit plays a critical role in modern industrial and commercial refrigeration applications. As businesses seek reliable, efficient, and flexible refrigeration solutions, understanding the differences between standard and custom-built units becomes essential.

Understanding standard V-type box condensing units

Definition and general features

A standard V-type box condensing unit refers to a pre-designed, off-the-shelf refrigeration system produced in fixed configurations. These units typically have a predetermined structure, refrigerating capacity, and connection methods suitable for a wide range of applications. Standard units are often preferred in projects with common cooling requirements, such as small commercial refrigeration, medium-sized warehouses, or general process cooling.

Advantages of standard units

Standard units offer quick availability and predictable performance, making them suitable for applications that do not require specialized parameters. Because the design is fixed, manufacturers can optimize production for cost efficiency and reliability. They usually comply with standard industry certifications, ensuring safety, environmental compliance, and basic quality assurance.

Limitations of standard units

However, standard V-type box condensing units have inherent limitations. Their fixed design may not accommodate specific space constraints, unusual refrigerant requirements, or unique operational conditions. Additionally, in high-demand environments where cooling precision or system efficiency is critical, standard units may not provide optimal performance. This is particularly relevant for industries with strict temperature control requirements, such as pharmaceutical storage or marine refrigeration.

The concept of custom-built V-type box condensing units

Tailored design for specific applications

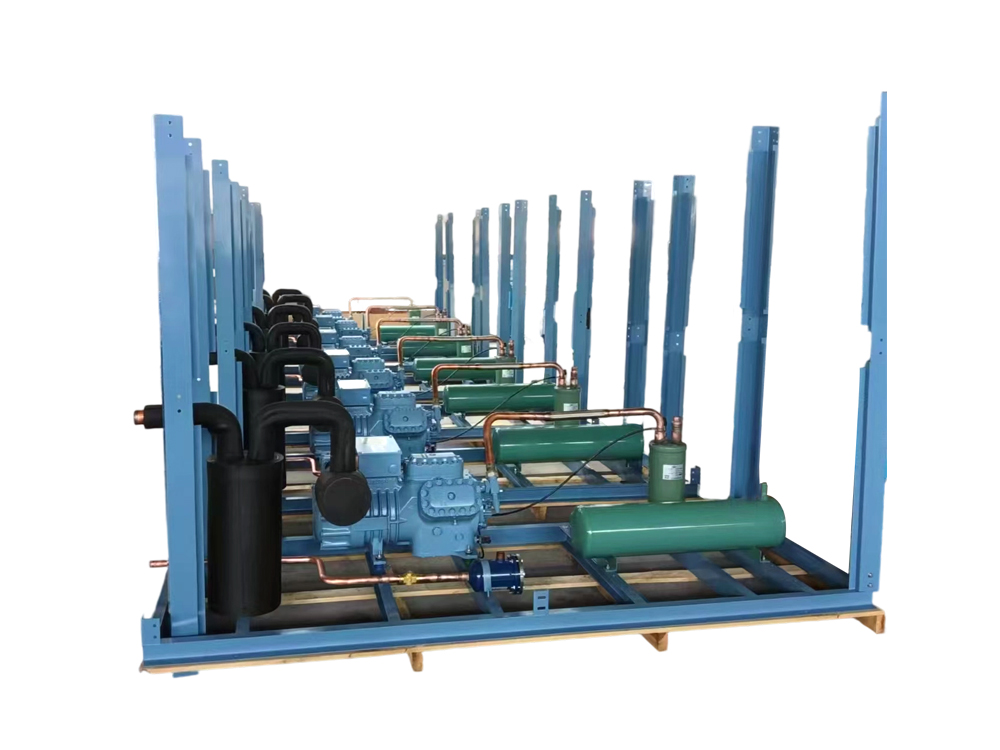

A custom-built V-type box condensing unit is engineered to meet precise requirements defined by the end-user. Customization extends to structural dimensions, refrigerating capacity, connection methods, and modular configurations. By tailoring these parameters, manufacturers ensure the unit integrates seamlessly with existing systems while delivering maximum efficiency and reliability.

Zhejiang Diya Refrigeration Equipment Co., Ltd. has extensive experience in non-standard customization. Its engineering design team, including specialists in mechanical engineering, thermodynamics, and structural optimization, allows for rapid adjustments of key parameters, ensuring that each unit meets the unique demands of industries such as food cold chain logistics, commercial refrigeration, and industrial process cooling.

Performance optimization

Custom-built units enable enhanced cooling performance. By analyzing the specific environmental conditions, load requirements, and operational constraints, engineers can optimize heat transfer efficiency, airflow patterns, and compressor selection. For instance, the choice of a particular compressor brand or type can significantly affect energy consumption, noise levels, and reliability. In high-capacity industrial applications, this optimization translates into substantial cost savings and operational stability.

Structural and modular flexibility

One of the most significant benefits of custom-built units is structural adaptability. Custom designs can accommodate unique installation spaces, unusual airflow requirements, and special mounting conditions. Modular combination design, a feature emphasized by Diya, allows for interchangeable components, reducing maintenance costs and simplifying future upgrades. For industries that frequently adjust operational setups, such modularity is highly valuable.

Key technical differences between standard and custom-built units

Refrigeration performance customization

Standard units are manufactured to provide adequate cooling for common conditions, but they often cannot achieve the fine-tuned performance required in specialized applications. Custom-built V-type box condensing units allow precise calibration of refrigerating capacity, heat rejection, and system response to match the load and environmental variables.

Compressor selection and adaptation

The compressor is the heart of any condensing unit. In standard units, the compressor type and brand are typically fixed. Custom-built units, however, allow for compressor brand adaptation. Depending on the application, engineers can select compressors with specific efficiency ratings, duty cycles, or refrigerant compatibility, ensuring long-term operational reliability.

Structural design considerations

Custom units often incorporate non-standard structural designs to accommodate installation constraints or optimize airflow and heat dissipation. For instance, angled coil arrangements, reinforced frames, or specialized casings can improve performance and durability under demanding conditions. Standard units are less flexible, with fixed dimensions that may not be ideal for every installation scenario.

Connection and piping modifications

Custom units also allow for specialized piping layouts, connection sizes, and service ports. This ensures compatibility with existing refrigeration networks or complex cold chain systems. Standard units, while easier to install, may require additional adaptations or modifications on-site, potentially increasing labor costs.

Industry-specific applications

Food cold chain

In food processing and storage, precise temperature control is critical to maintaining product quality. Custom-built V-type box condensing units can be tailored to achieve specific cooling capacities, refrigerant types, and airflow distributions, minimizing temperature fluctuations. Standard units may suffice for general storage, but high-volume warehouses often require customized solutions.

Pharmaceutical and healthcare

Pharmaceutical storage facilities often require extremely tight temperature and humidity tolerances. A custom-built V-type box condensing unit allows for specialized design considerations, such as redundancy, alarm systems, and compatible refrigerants, ensuring compliance with regulatory standards. Standard units may not meet these stringent specifications.

Commercial refrigeration

Retail supermarkets and cold storage facilities benefit from units that maximize efficiency while minimizing noise. Custom-built units can be designed to fit confined spaces, incorporate energy-efficient compressors, and maintain optimal performance across variable loads. Standard units provide a reliable baseline but may lack flexibility in crowded or architecturally constrained installations.

Industrial process cooling

Industrial processes, such as chemical manufacturing or heavy machinery cooling, often generate highly variable heat loads. Custom-built V-type box condensing units allow engineers to design systems that adapt to these fluctuations, improving energy efficiency and ensuring consistent cooling. Standard units may operate below or above optimal efficiency in such variable conditions.

Safety, environmental, and quality considerations

Compliance with industry standards

Both standard and custom-built units must comply with safety, environmental, and operational standards. Custom-built V-type box condensing units are often designed to meet additional local regulations and certification requirements, which is particularly important in international markets. Diya demonstrates this commitment through strict adherence to quality control and environmental responsibility.

Reliability and maintenance

Custom units allow for modular designs and accessible components, simplifying routine maintenance and reducing downtime. Standard units may be more limited in this regard, particularly if installed in specialized or hard-to-access locations.

Environmental responsibility

Refrigerant selection and energy efficiency are key considerations in modern refrigeration systems. Custom-built units can utilize low-GWP refrigerants, energy-efficient compressors, and optimized heat exchange surfaces, aligning with environmental goals. Standard units may use conventional refrigerants and fixed designs, offering fewer options for reducing environmental impact.

Comparative overview

| Feature |

Standard V-type box condensing unit |

Custom-built V-type box condensing unit |

| Design flexibility |

Limited |

High; tailored to application |

| Refrigeration capacity |

Fixed |

Adjustable to load requirements |

| Compressor options |

Standard |

Brand/type selection possible |

| Modular components |

Basic |

Advanced modular combination design |

| Installation adaptability |

Moderate |

Can accommodate non-standard spaces |

| Maintenance ease |

Standard access |

Optimized for accessibility and future upgrades |

| Application-specific optimization |

General |

Highly optimized for specific industry needs |

| Energy efficiency |

Average |

Can be enhanced for efficiency and environmental standards |

Decision-making considerations

When choosing between a standard or custom-built V-type box condensing unit, several factors must be evaluated:

- Application requirements: Consider the cooling load, space constraints, and precision required for temperature control.

- Operational environment: Take into account ambient temperatures, installation conditions, and noise restrictions.

- Long-term cost: Factor in energy efficiency, maintenance requirements, and potential modifications to standard units.

- Regulatory compliance: Ensure the unit meets local and industry-specific safety and environmental standards.

- Scalability: Evaluate the need for modularity, future expansion, or system upgrades.

For industries with specialized needs or stringent operational conditions, investing in a custom-built unit often provides the most reliable, efficient, and cost-effective solution.

Conclusion

The choice between a standard and custom-built V-type box condensing unit depends on operational requirements, environmental conditions, and industry-specific demands. While standard units provide reliable, readily available solutions suitable for many applications, custom-built units offer tailored performance, structural flexibility, and long-term efficiency, particularly in specialized industries such as food cold chain, pharmaceuticals, and industrial process cooling.

By leveraging expert engineering design, modular concepts, and refrigeration performance customization, manufacturers like Zhejiang Diya Refrigeration Equipment Co., Ltd. provide solutions that combine efficiency, safety, and adaptability. Understanding the differences between standard and custom-built units enables informed decision-making, ensuring optimal refrigeration performance and operational success across diverse industries.

English

English русский

русский Español

Español