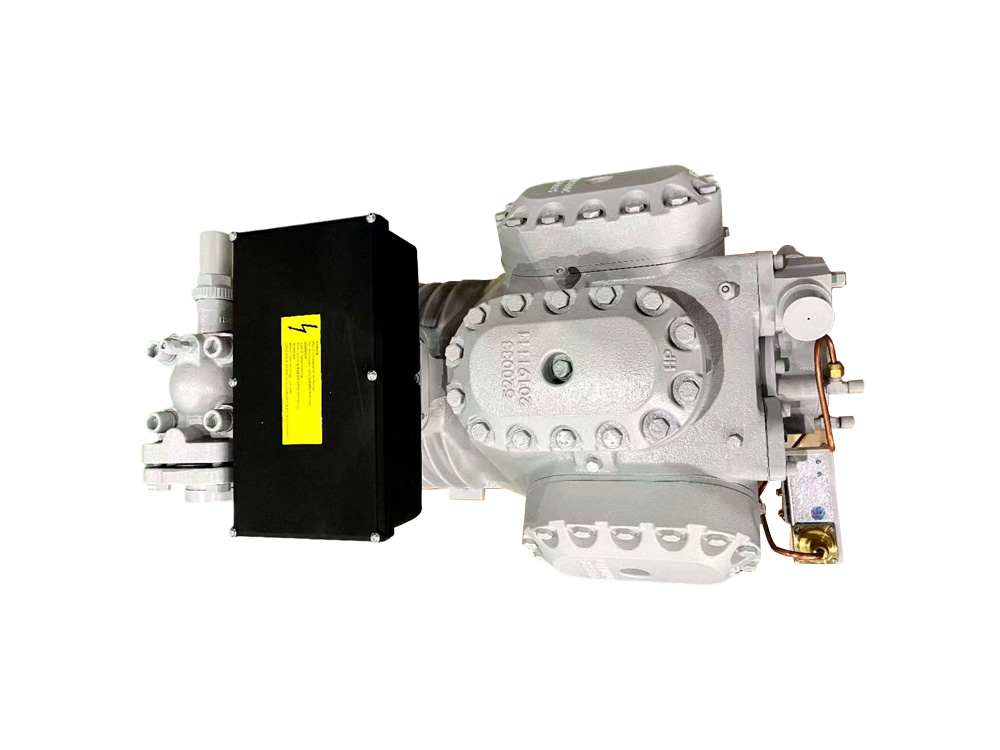

Anatomy of a Powerhouse: A Detailed Look at the 5 Key Technical Parameters of a 6-Cylinder Compressor

As the "heart" of large-scale industrial refrigeration systems, the exceptional performance of a 6-cylinder compressor stems from a series of precisely engineered core technical parameters. This article provides an in-depth analysis of the five key indicators that determine its power, efficiency, and reliability, helping you understand from a technical perspective why it is the ultimate choice for heavy-duty applications.

Key Parameters to Master

- Displacement: Measured in m³/h, this directly determines the compressor's theoretical gas delivery capacity, serving as the most fundamental parameter for measuring its "power."

- Cooling Capacity: Measured in kW, this refers to the actual cooling capacity under specific operating conditions (e.g., -10°C evaporating / 40°C condensing). It is the core basis for model selection.

- Capacity Control Range: Usually expressed as a percentage, such as "33%-66%-100%," this indicates the compressor's ability to perform multi-stage unloading to adapt to part-load operation, which is key to energy saving.

- COP/EER (Coefficient of Performance / Energy Efficiency Ratio): This metric measures the energy utilization efficiency of the compressor. A higher value means less electricity is consumed to produce the same amount of cooling capacity.

- Materials and Craftsmanship of Moving Parts: Whether components like the crankshaft, connecting rods, and pistons are made of high-strength alloy steel, or if the cylinders have wear-resistant coatings, directly determines the durability of the equipment.

Commitment to Engineering Excellence

As a modern enterprise focused on refrigeration technology R&D since its establishment in 1983, Zhejiang Diya Refrigeration Equipment Co., Ltd. possesses a profound understanding and strict control over these core parameters. We integrate R&D and manufacturing, operating our own factory under an ISO9001 quality system to ensure that the displacement, energy efficiency, and durability of every 6-cylinder compressor meet first-class international standards, providing a stable and reliable power core for clients worldwide.

From 2 to 6 Cylinders: A Comprehensive Comparative Analysis of Performance Impact in Reciprocating Compressors

In the family of reciprocating compressors, increasing the number of cylinders is more than just a numerical change; it's a leap in performance. This article provides a detailed comparative analysis, systematically explaining the evolution and differences in cooling capacity, vibration, energy efficiency, and application scenarios from 2-cylinder to 4-cylinder and finally to 6-cylinder models, offering you a clear roadmap for selection.

Comparative Performance Metrics

- Operational Smoothness: A 6-cylinder compressor, with its evenly distributed crankshaft angles, has minimal torque fluctuation, resulting in significantly lower vibration and noise compared to models with fewer cylinders.

- Part-Load Efficiency: 6-cylinder compressors typically feature more precise capacity control (e.g., three or four-step regulation), achieving a significantly higher COP at part-load than 2 or 4-cylinder models.

- Load per Cylinder: For the same total displacement, each cylinder in a 6-cylinder compressor bears a smaller load, leading to more even wear and a longer service life.

- Initial Investment vs. Maintenance Cost: A 6-cylinder compressor has the highest initial cost, but its high reliability and long lifespan can reduce long-term maintenance costs and downtime losses.

- Applicable Cooling Capacity Range: 2-cylinder (small), 4-cylinder (medium), 6-cylinder (large and above), together covering the full spectrum of applications from small commercial to large industrial.

A Full Spectrum of Expertise

Zhejiang Diya Refrigeration Equipment Co., Ltd. boasts a comprehensive product line, mastering the manufacturing processes of the full range of reciprocating compressors from 2 to 6 cylinders. Our products, known for their outstanding performance, have passed rigorous certifications like CE and are successfully exported to various regions with diverse climates and application needs, such as the Middle East, Southeast Asia, Europe, and the Americas. This proves our ability to provide the most suitable cylinder configuration based on a client's specific needs, rather than promoting a one-size-fits-all model.

Bigger Than Power: High-Efficiency and Precise Control Strategies of 6-Cylinder Compressors in Industrial Refrigeration

Often seen as synonymous with "high power," the true value of a 6-cylinder compressor lies in its "high efficiency" and "intelligence." This article focuses on how 6-cylinder compressors achieve exceptional energy efficiency in large systems and, through advanced capacity control strategies, realize on-demand output, thereby minimizing operational costs while ensuring cooling effectiveness.

Key Parameters and Strategies

- Multi-Stage Unloading Control: Uses solenoid valves to cause some cylinders to idle, achieving stepwise cooling capacity output (e.g., 100%, 66%, 33%) and avoiding wasted energy consumption.

- Variable Frequency Drive (VFD) Technology: Combined with a VFD, it enables seamless, linear regulation of cooling capacity, perfectly matching the compressor's output to real-time load for optimal energy efficiency ratio.

- Parallel Operation Optimization: Multiple 6-cylinder compressors operating in parallel, managed by an intelligent group control system, can take turns running or start/stop on demand, keeping the entire system operating within a high-efficiency range.

- Performance Advantages in Low Evaporation Temperature Applications: In low-temperature applications like blast freezing, 6-cylinder compressors maintain high efficiency and reliability due to their robust construction and optimized pressure ratio design.

- Heat Recovery Applications: Utilizing waste heat from the compressor for hot water production or reuse further enhances the overall energy utilization efficiency of the system.

Your Partner in Efficient Solutions

As a comprehensive enterprise integrating R&D, design, sales, engineering installation, and after-sales service, Zhejiang Diya Refrigeration Equipment Co., Ltd. is more than just a manufacturer of 6-cylinder compressors; we are a provider of high-efficiency refrigeration system solutions. With over 40 years of engineering experience, we deeply understand how to maximize the performance potential of 6-cylinder compressors through refined control strategies, helping global clients build green and energy-saving industrial refrigeration systems.

Guardian of the Industrial Giant: Durability Design and Key Maintenance Points for a 6-Cylinder Compressor

In industrial fields requiring 24/7 uninterrupted operation, equipment reliability is the top priority. As the "industrial giant" of the system, the durability design of a 6-cylinder compressor is critical. This article delves into its robust structural design and provides key maintenance points to ensure this core piece of equipment can operate stably for the long term.

Key Design and Maintenance Points

- Block Material: Utilizes high-strength gray cast iron or ductile iron, which offers excellent vibration damping and sound absorption while withstanding high pressures.

- Crankshaft and Bearings: Employs forged alloy steel crankshafts paired with multi-support, large-size precision bearings to ensure stable and durable power transmission.

- Pistons and Connecting Rods: Lightweight, high-strength aluminum alloy pistons combined with case-hardened steel connecting rods reduce inertial forces and minimize wear.

- Forced Lubrication System: Uses an oil pump for forced lubrication, ensuring all moving parts receive adequate oil film protection even under extreme operating conditions.

- Key Maintenance Points: Regularly check oil level and quality; periodically clean or replace the oil filter; monitor operational vibration and noise; check the operational status of capacity control solenoid valves.

Built for a Lifetime of Service

Since the establishment of our factory in 1983, Zhejiang Diya Refrigeration Equipment Co., Ltd. has regarded product durability as its lifeline. Our own factory implements quality inspection processes for every core component of a 6-cylinder compressor—from casting and machining to assembly—that far exceed industry standards. Our products are exported to markets with extremely high demands on equipment reliability, such as those in Africa and the Americas, which is the best testament to the durability of our designs.

Deep Dive into Application Scenarios: Which Industries Rely on the Immense Power of 6-Cylinder Compressors?

A 6-cylinder compressor is not suitable for every application; it is built for the most demanding and challenging refrigeration needs. This article provides an in-depth analysis of the specific application cases of 6-cylinder compressors in various key industries, showcasing their irreplaceable value and immense power through real-world scenario requirements.

Key Application Scenarios

- Large-Scale Food Processing and Freezing Warehouses: Used in blast freezing tunnels and large-scale cold storage for meat and seafood, requiring the removal of a massive amount of heat in a short time and providing continuous, stable low temperatures.

- Artificial Ice and Snow Environments: Ice-making systems for large ski resorts and skating rinks require long-duration, high-load, high-precision maintenance of the ice surface temperature.

- Chemical and Pharmaceutical Industries: Providing low-temperature chilled water or brine for process equipment like reactors and distillation columns, where extremely high demands are placed on temperature control precision and system stability.

- District Cooling: Serving as the cold source for district cooling plants, providing chilled water for entire commercial or residential areas, which requires equipment with extremely high reliability and regulation capabilities.

- Large Data Centers and IDCs: Providing precision cooling for high-density server racks. While centrifugal compressors are common, large reciprocating compressors (like 6-cylinder models) still have their application space in certain specific conditions or as backup systems.

Global Expertise in Diverse Industries

As a modern enterprise with products sold globally, Zhejiang Diya Refrigeration Equipment Co., Ltd. possesses extensive project experience in many of the industries listed above. We not only provide high-quality 6-cylinder compressors but also offer "one-stop" solutions, from system design and engineering installation to after-sales service, tailored to the specific process requirements of different industries. No matter where your project is located, we can provide the most professional and timely support through our global service network.

English

English русский

русский Español

Español