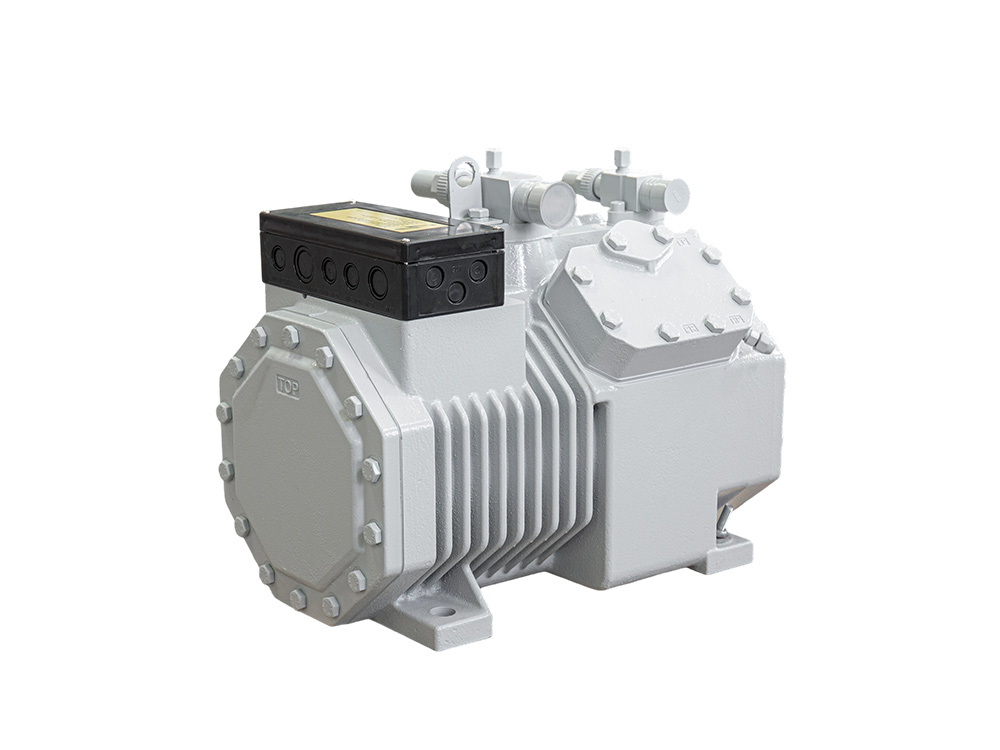

The 4-Cylinder Compressor: Engineering Excellence for Industrial Refrigeration

In the realm of large-scale commercial and industrial refrigeration, the demand for power, reliability, and efficiency is uncompromising. The 4-cylinder compressor stands as a pinnacle of piston compressor technology, engineered to meet these rigorous demands. This guide explores the advanced features and applications of this industrial workhorse, incorporating the manufacturing expertise of Zhejiang Diya Refrigeration Equipment Co., Ltd., a global leader with a legacy of innovation since 1983.

1. The Heart of Stability: Achieving Unmatched Smoothness and Low Vibration

In large-scale installations, minimizing vibration and noise is critical for structural integrity and operational comfort. The 4-cylinder compressor, with its four cylinders symmetrically arranged at 90-degree angles, represents the zenith of mechanical balance in reciprocating technology.

- Vibration Velocity: Typically controlled below 2.8 mm/s, significantly under common international standards.

- Noise Levels: Full-load sound power levels can be as low as 70 dB(A) at one meter.

- Crankshaft Balancing: Precision-balanced to G2.5 grade or higher, eliminating vibration at its source.

Leveraging decades of heavy machinery manufacturing experience since 1983, Zhejiang Diya ensures its 4-cylinder compressors deliver unparalleled smoothness. This makes them ideal for vibration-sensitive installations like rooftop placements or precision manufacturing facilities, fully complying with the stringent safety and environmental requirements of CE certification.

2. Precision Energy Control: Mastering Multi-Stage Capacity Regulation

For large systems with fluctuating loads, the capacity modulation capabilities of a 4-cylinder compressor are key to precise cooling and profound energy savings. This technology perfectly matches output to real-time demand.

- Capacity Steps: Achieves 25%-50%-75%-100% three-step unloading, or seamless 0-100% control when combined with variable-speed drives.

- Part-Load Efficiency: At 50% load, the Integrated Part-Load Value (IPLV) can be over 30% higher than that of fixed-speed models.

- Control Response: Utilizes PLC controllers and high-precision pressure sensors for rapid load response and superior system pressure stability.

As a modern enterprise integrating R&D, design, and manufacturing, Zhejiang Diya robustly incorporates this advanced capacity regulation into its 4-cylinder series, delivering significant operational cost savings to global clients, particularly in regions with high energy costs like Europe and the Middle East.

3. Built for 24/7 Operation: Industrial-Grade Reliability Engineering

Major industrial projects cannot afford unscheduled downtime. The 4-cylinder compressor is engineered for non-stop operation, with reliability founded on robust design principles.

- Bearing Design Life: Critical bearings feature a B10 life exceeding 100,000 hours, supporting continuous, year-round operation.

- Forced Lubrication System Pressure: The oil pump maintains a stable pressure of 3.0 - 5.0 Bar, ensuring adequate lubrication to all four cylinders even at extremely low evaporation temperatures.

- Motor Insulation Class: Equipped with Class F or H insulation, providing a substantial safety margin for motor windings in high-ambient conditions.

Within its own factory, backed by an ISO9001 quality management system, Zhejiang Diya subjects every core component of its 4-cylinder compressors to rigorous testing, ensuring they are fit for the world's most demanding industrial applications, such as chemical plants and large-scale cold chain logistics centers.

4. The Foundation for High-Capacity Applications: Power Range and System Integration

The 4-cylinder compressor is the ideal choice for medium to high-capacity refrigeration systems, providing a stable and reliable power core for large projects. Zhejiang Diya's product series is designed to meet diverse global needs.

- Power Range: Typically covers 15 HP to 60 HP, serving as the primary driver for large cold storage and district cooling systems.

- Refrigerant Compatibility: Fully compatible with R22, R404A, R507A, R134a, and adaptable to newer options like R513A.

- System Design Flexibility: Effective as a single unit and ideal for building parallel compressor racks, offering N+1 redundancy and a wider capacity range through multi-unit configuration.

With an integrated chain from sales and engineering installation to after-sales service, Zhejiang Diya provides turnkey solutions for large projects worldwide, from the core compressor to complete system integration.

5. Maximizing Lifecycle Value: Predictive Maintenance and Long-Term Management

For a critical asset like a 4-cylinder compressor, maintenance strategy must evolve from reactive repair to predictive care. Based on extensive global service data from Zhejiang Diya, focusing on these key areas maximizes asset value.

Oil Analysis

- Recommended Interval: Perform oil analysis every 2,000 operating hours or at least annually to monitor metal wear particles and acidity.

Performance Trend Monitoring

- Suction/Discharge Pressures & Temperatures: Continuous logging; declining efficiency is an early indicator for maintenance.

- Operating Current & Voltage: Monitor three-phase balance; deviation should not exceed 2%.

Mechanical Condition Monitoring

- Vibration Analysis: Use professional equipment periodically to establish a baseline and detect early bearing or alignment issues.

- Infrared Thermography: Regularly scan motors and terminal connections to identify abnormal hot spots.

Zhejiang Diya's global service network ensures that clients across the Middle East, Southeast Asia, Africa, Europe, and the Americas receive data-driven maintenance advice, genuine spare parts, and rapid technical support, truly safeguarding the long-term return on their investment.

English

English русский

русский Español

Español