How Water Defrosting Air Coolers Improve Energy Efficiency in HVAC Systems

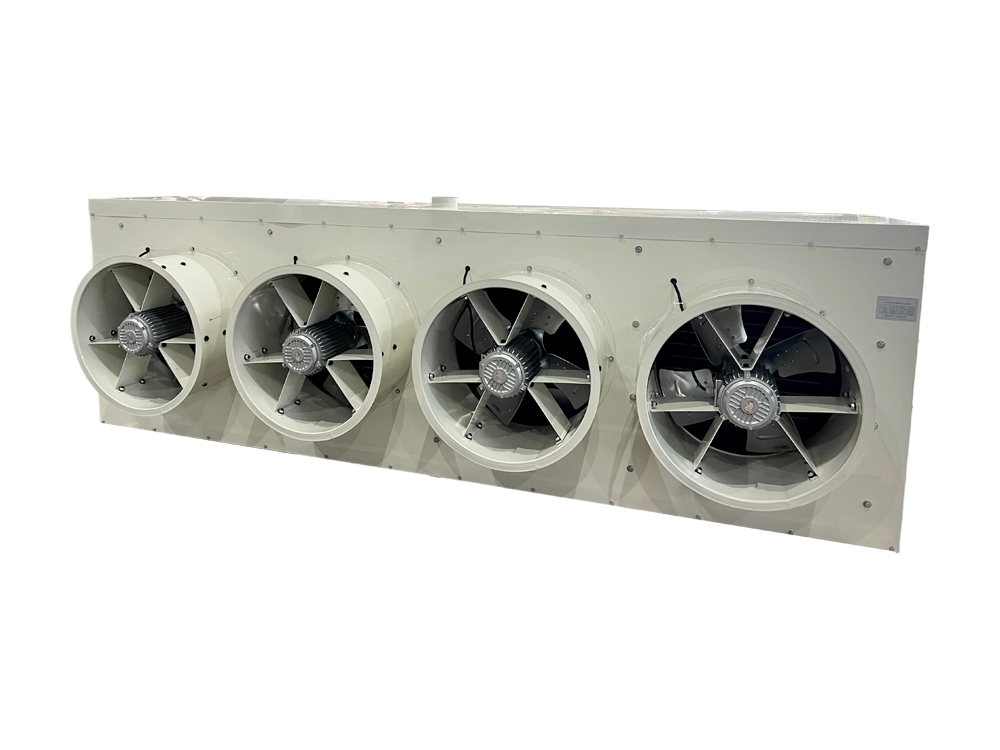

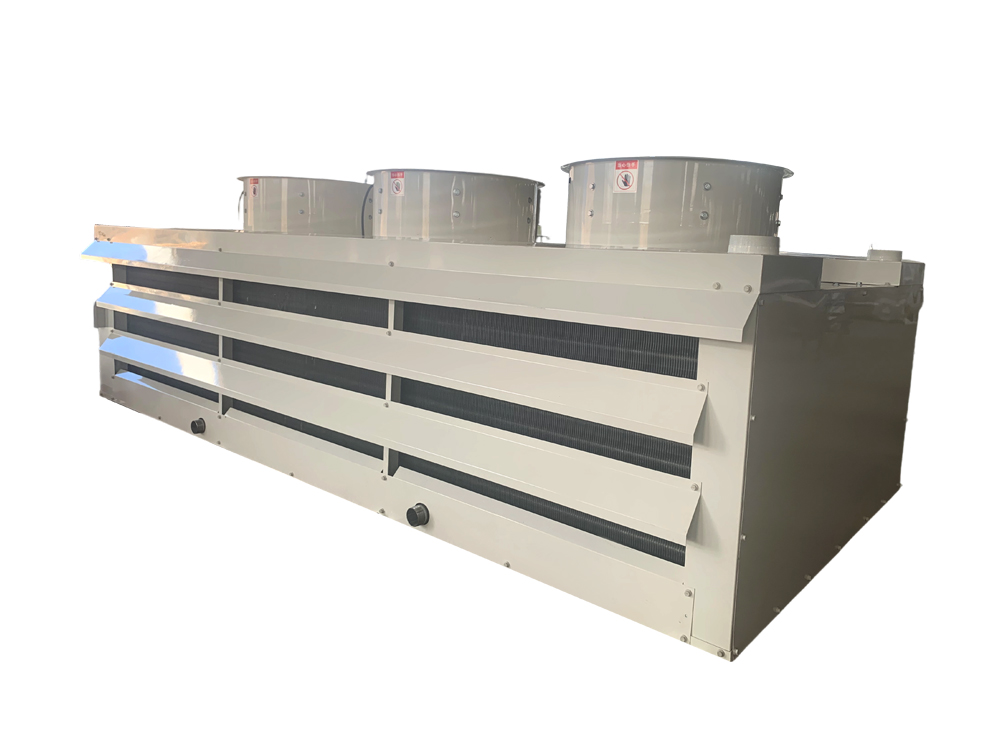

Water defrosting air coolers (WDACs) are specialized HVAC components designed to prevent ice formation on cooling coils in low-temperature environments. By integrating water-based defrosting, these systems maintain optimal heat exchange efficiency and reduce energy waste. Here’s how they improve energy efficiency:

1. Preventing Ice Accumulation

In conventional air coolers, ice can form on the evaporator coils in cold environments. This ice acts as an insulating layer, reducing heat transfer and forcing the system to work harder. Water defrosting air coolers use controlled water flow to melt ice quickly, ensuring coils remain clean and fully functional. This reduces the energy required to maintain the desired temperature.

2. Reducing Compressor Load

By preventing ice buildup, WDACs reduce the workload on compressors. When coils are iced over, compressors must operate longer and at higher power to achieve target cooling. Water defrosting minimizes this extra load, which directly lowers electricity consumption and extends equipment lifespan.

3. Optimizing Airflow

Ice accumulation can block airflow, causing uneven cooling and forcing fans to operate at higher speeds. WDACs maintain unobstructed airflow by removing ice, which allows fans to operate efficiently at designed speeds, further reducing energy use.

4. Shorter Defrost Cycles

Compared to electric or hot-gas defrost methods, water defrosting uses lower-energy water flow to remove ice. This method requires less power and reduces downtime during defrost cycles, improving overall system efficiency.

5. Enhanced System Control

Many modern WDACs integrate smart sensors to monitor temperature, humidity, and ice formation. Automated water defrosting is applied only when necessary, avoiding unnecessary energy expenditure and optimizing operational efficiency.

Water defrosting air coolers offer a practical and energy-efficient solution for maintaining HVAC performance in cold or humid environments. By preventing ice accumulation, reducing compressor load, and optimizing airflow, they can significantly lower energy consumption while extending the service life of cooling equipment.

Comparing Water Defrosting Air Coolers with Traditional Air Cooling Solutions

Water defrosting air coolers (WDACs) and traditional air cooling solutions are both widely used in industrial and commercial refrigeration systems. However, WDACs offer several advantages in efficiency, maintenance, and operational flexibility, making them a preferred choice in many modern applications. Zhejiang Diya Refrigeration Equipment Co., Ltd., a leading Chinese refrigeration enterprise founded in 1983, has developed advanced WDAC systems that exemplify these advantages.

1. Ice Management and Efficiency

Traditional air coolers often rely on electric or hot-gas defrosting, which can be energy-intensive and cause periodic downtime. In contrast, WDACs use controlled water defrosting to prevent ice buildup on evaporator coils. This ensures optimal heat transfer and reduces the energy required to maintain target temperatures, improving overall system efficiency.

2. Energy Consumption

By maintaining clean coils and avoiding extended defrost cycles, WDACs reduce compressor and fan workload compared to traditional systems. This not only saves electricity but also reduces wear on mechanical components, lowering maintenance costs over the system lifecycle.

3. Operational Flexibility

WDACs are better suited for environments with fluctuating temperatures or high humidity, as they can respond dynamically to ice formation without requiring complete system shutdowns. Traditional air coolers may experience performance degradation under similar conditions.

4. Maintenance and Longevity

The water-based defrosting process is gentler on coils than high-temperature electric defrosting, leading to less thermal stress and longer equipment lifespan. In addition, the reduced buildup of ice and frost simplifies routine maintenance.

5. Application Range

Companies like Zhejiang Diya Refrigeration Equipment Co., Ltd. have designed WDACs that integrate seamlessly with their air-cooled/water-cooled condensers, screw compressor units, and chillers, making them versatile for use in food cold chain, industrial process cooling, pharmaceutical warehousing, commercial refrigeration, marine refrigeration, and logistics cold chain systems.

Example Comparison Table

| Feature |

Water Defrosting Air Cooler |

Traditional Air Cooler |

| Defrost Method |

Water-based |

Electric or hot-gas |

| Energy Efficiency |

High |

Moderate |

| Ice Accumulation |

Minimal |

Can be significant |

| Maintenance Requirements |

Lower |

Higher |

| Operational Flexibility |

High |

Moderate |

| Equipment Lifespan |

Longer |

Shorter |

Water defrosting air coolers offer superior efficiency, flexibility, and reduced maintenance compared to traditional air cooling solutions. Zhejiang Diya Refrigeration Equipment Co., Ltd. leverages over 40 years of experience to design reliable, high-performance WDAC systems, supporting a wide range of industrial and commercial refrigeration applications.

English

English русский

русский Español

Español