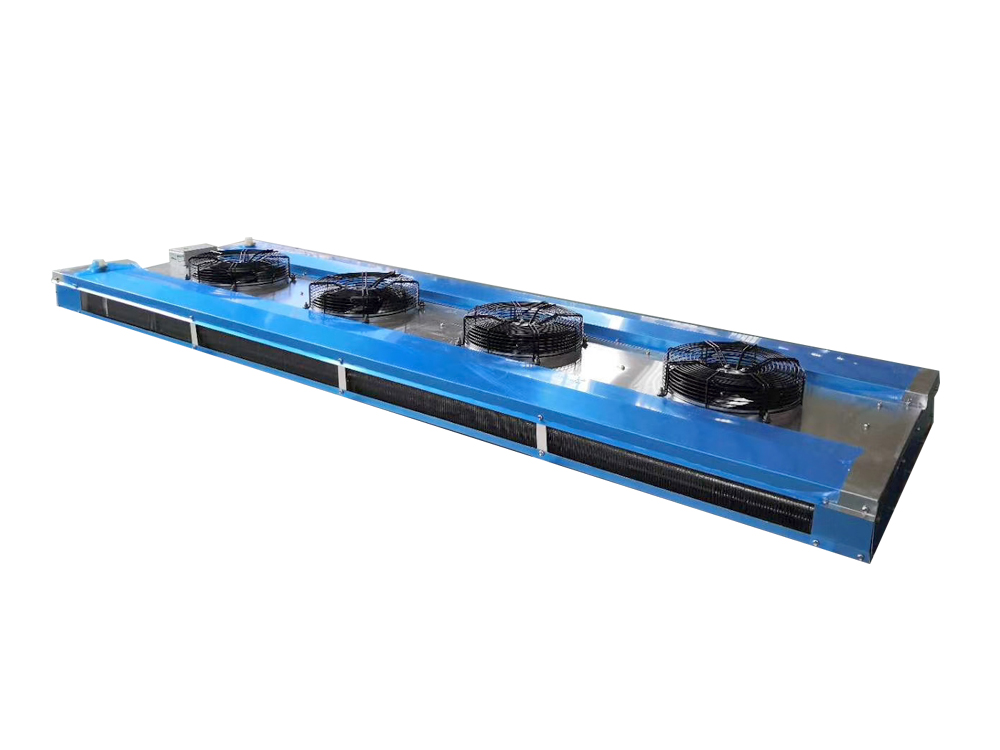

How Aluminum Plate Shell Air Coolers Improve Energy Efficiency and Heat Exchange

Aluminum plate shell air coolers are widely used in industrial and commercial cooling systems due to their high thermal efficiency, lightweight construction, and durability. Here’s how they enhance energy efficiency and heat exchange performance:

1. High Thermal Conductivity of Aluminum

Aluminum has excellent thermal conductivity compared to many other metals. In a plate shell air cooler, the aluminum plates facilitate rapid heat transfer from the coolant to the air, ensuring faster and more efficient cooling. This reduces the energy required for the system to achieve the desired temperature.

2. Optimized Plate Design

The plates in the cooler are designed with fins, corrugations, or microchannels to increase the surface area exposed to airflow. The larger contact area enhances heat dissipation, allowing the system to operate efficiently at lower energy input.

3. Lightweight and Corrosion-Resistant Structure

Aluminum’s lightweight nature reduces the load on supporting structures and fans, which can lower operational energy consumption. Additionally, aluminum’s resistance to corrosion extends the life of the cooler and maintains its thermal performance over time without efficiency losses.

4. Efficient Airflow Management

Aluminum plate shell coolers are engineered to maximize airflow while minimizing resistance. Proper airflow design ensures uniform heat distribution and prevents hotspots, reducing the need for higher fan speeds and thus saving electricity.

5. Compact and Modular Design

The compact design of aluminum plate shell air coolers allows for closer spacing of plates, which reduces the coolant volume needed and shortens the heat transfer path. Modular units can be scaled to match the cooling demand precisely, avoiding energy waste associated with oversized systems.

6. Reduced Fouling and Maintenance Needs

The smooth surface of aluminum plates reduces dust and debris accumulation, which can otherwise hinder heat transfer. Less fouling means consistent heat exchange efficiency and lower energy consumption for cleaning and maintenance.

Conclusion

By combining high thermal conductivity, optimized plate design, efficient airflow, and a lightweight, corrosion-resistant structure, aluminum plate shell air coolers significantly enhance heat exchange while reducing energy consumption. These features make them an ideal choice for energy-conscious industrial cooling applications.

Comparing Aluminum Plate Shell Air Coolers with Traditional Air Cooler Designs

Aluminum plate shell air coolers have become increasingly popular in industrial and commercial refrigeration due to their high efficiency, durability, and lightweight design. Compared to traditional air cooler designs, these units offer several significant advantages. Zhejiang Diya Refrigeration Equipment Co., Ltd., founded in 1983, has over 40 years of experience in developing advanced refrigeration products, including air coolers, condensers, screw compressor units, and integrated systems. Their aluminum plate shell air coolers reflect decades of engineering optimization for various industries such as food cold chain, industrial process cooling, pharmaceuticals, commercial refrigeration, marine refrigeration, and logistics cold chain.

Key Differences

| Feature |

Aluminum Plate Shell Air Coolers |

Traditional Air Coolers |

| Material |

High-quality aluminum plates, corrosion-resistant, lightweight |

Steel or copper-based, heavier, may corrode over time |

| Thermal Efficiency |

High thermal conductivity of aluminum enables faster and more uniform heat exchange |

Lower efficiency due to less conductive materials and simpler plate/fan design |

| Energy Consumption |

Optimized plate spacing and airflow design reduce fan energy usage |

Higher fan speeds often required to achieve desired cooling |

| Maintenance |

Smooth aluminum surfaces resist fouling, easier cleaning, longer service life |

Prone to scale buildup, requires more frequent maintenance |

| Design Flexibility |

Compact, modular units suitable for different cooling capacities and layouts |

Typically bulkier and less adaptable to changing space or load requirements |

| Application Range |

Widely used in cold chain logistics, industrial processes, commercial refrigeration, and pharmaceuticals |

Limited by size, efficiency, and corrosion issues |

Advantages of Aluminum Plate Shell Air Coolers

- Enhanced Heat Transfer: Aluminum’s superior thermal conductivity ensures rapid and uniform cooling, improving overall system efficiency.

- Energy Savings: Optimized airflow and lightweight construction reduce energy consumption compared to traditional air coolers.

- Durability and Longevity: Corrosion resistance and smooth surfaces prolong the cooler’s operational life.

- Modular and Scalable: Units can be designed to meet specific cooling demands without oversizing the system.

- Lower Maintenance Costs: Reduced fouling and easy cleaning decrease downtime and maintenance expenses.

By leveraging advanced materials and engineering, aluminum plate shell air coolers from Zhejiang Diya Refrigeration Equipment Co., Ltd. offer superior thermal performance, energy efficiency, and long-term reliability compared to traditional air cooler designs. They are well-suited for modern industrial and commercial refrigeration applications where efficiency, durability, and flexibility are key.

English

English русский

русский Español

Español