How to Choose the Right Freezer Condenser Unit for Commercial Refrigeration Systems

Choosing the right freezer condenser unit for commercial refrigeration systems is crucial for ensuring optimal performance, energy efficiency, and long-term reliability. Several factors should be considered:

1. Cooling Capacity

The cooling capacity of a condenser unit must match the refrigeration load of your freezer system. An undersized unit will struggle to maintain the desired temperature, while an oversized unit may lead to inefficient energy use and higher operational costs. Always calculate the total thermal load, including ambient temperature, product load, and insulation quality.

2. Type of Condenser

Freezer condenser units typically come in air-cooled or water-cooled configurations:

- Air-cooled condensers are easier to install and require less maintenance but can be affected by ambient temperature and dust accumulation.

- Water-cooled condensers offer higher efficiency and more consistent cooling, especially in large-scale commercial setups, but require a water source and more complex maintenance.

3. Refrigerant Compatibility

Ensure the unit is compatible with the refrigerant used in your system. Modern refrigeration often uses eco-friendly refrigerants such as R290 or R404A. Using incompatible refrigerants can damage the system and violate regulations.

4. Energy Efficiency

Look for units with high energy efficiency ratings or features like variable speed fans and advanced heat exchangers. Energy-efficient units reduce operating costs and help meet sustainability targets.

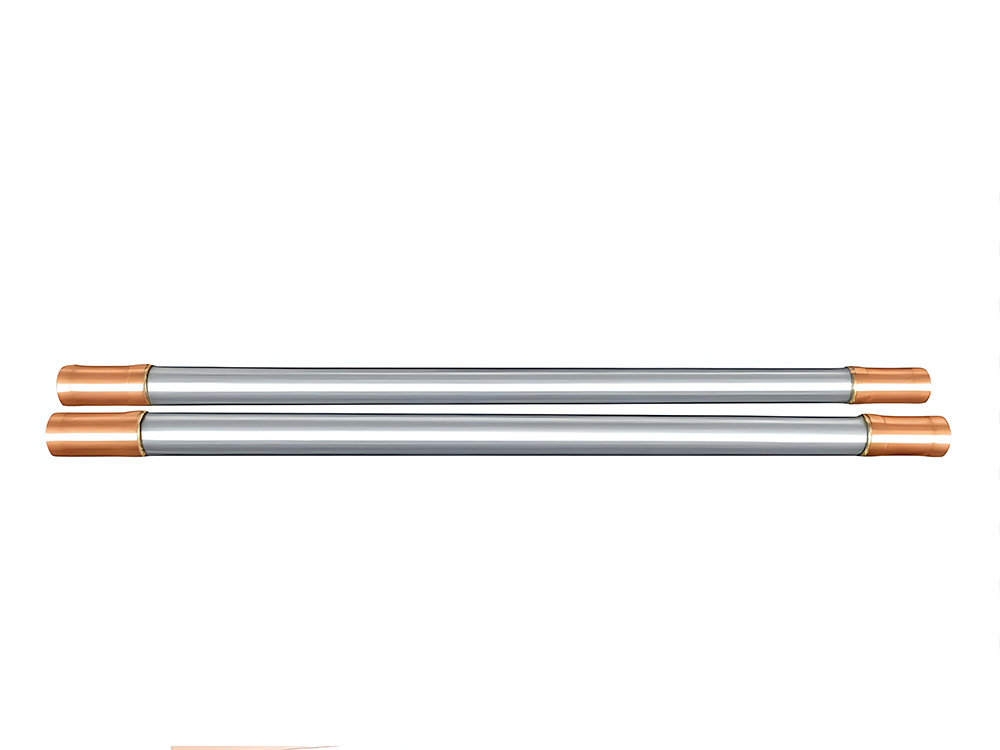

5. Durability and Material Quality

Commercial freezer environments can be harsh, with high humidity and low temperatures. Choose units made from corrosion-resistant materials like stainless steel or coated aluminum and robust components that withstand continuous operation.

6. Maintenance Requirements

Consider ease of access for cleaning and servicing. Units with modular designs or removable panels simplify maintenance, prolong system life, and reduce downtime.

7. Noise Level

For environments like supermarkets or restaurants, condenser noise may affect customer experience. Look for units with low-noise fans or sound-reducing enclosures if necessary.

8. Brand Reputation and Support

Opt for reputable manufacturers who provide technical support, spare parts availability, and warranty coverage. This ensures reliable performance and easier troubleshooting if issues arise.

Summary

Selecting the right freezer condenser unit requires balancing cooling capacity, type of condenser, energy efficiency, material durability, maintenance needs, and noise considerations. Careful planning ensures a reliable, cost-effective, and energy-efficient refrigeration system.

Role of Condensing Units in Cold Room Temperature Control

A condensing unit is a critical component in a cold room refrigeration system. Its primary function is to remove heat from the refrigerant after it has absorbed heat from the cold room, allowing the system to maintain a stable, low-temperature environment.

1. Heat Rejection

The condensing unit compresses the refrigerant gas coming from the evaporator and then releases the heat to the outside environment. This process ensures that the refrigerant can return to a liquid state and continue the cooling cycle efficiently. Without proper heat rejection, the cold room temperature would rise, compromising the storage conditions.

2. Temperature Regulation

By controlling the flow and pressure of the refrigerant, the condensing unit helps maintain precise temperature levels inside the cold room. Modern condensing units often include thermostatic or electronic controls to adjust cooling output based on the cold room’s temperature requirements.

3. Energy Efficiency

A well-designed condensing unit ensures that the refrigeration system operates efficiently. Efficient heat transfer reduces energy consumption, which is particularly important in commercial or industrial cold rooms that run continuously.

4. System Reliability

The condensing unit protects the overall refrigeration system. Proper sizing and maintenance prevent overloading, compressor failure, or fluctuations in temperature, which could spoil stored products.

5. Integration with Other Components

The condensing unit works closely with evaporators, compressors, and expansion devices. Its performance directly affects the cold room’s ability to maintain uniform cooling, making it essential for food safety, pharmaceutical storage, and other temperature-sensitive applications.

The condensing unit is the heart of a cold room’s temperature control system. It removes heat from the refrigerant, regulates pressure and flow, improves energy efficiency, ensures system reliability, and interacts seamlessly with other refrigeration components to maintain consistent low temperatures. Proper selection, installation, and maintenance are key to achieving optimal cold room performance.

English

English русский

русский Español

Español